Self-protected, Low-temperature Nanosolder

Nanosolders allow for increased capabilities in the formation of soldered interconnections for heat sensitive electronic packages. The desired characteristic of nanosolder is to have a low process temperature that does not damage base materials or components, while also having a high service temperature that allows the product to operate in harsh environments. A team of Sandia researchers created a robust nanosolder that meets these very objectives, and is inexpensive and easy-to-use in an assembly process.

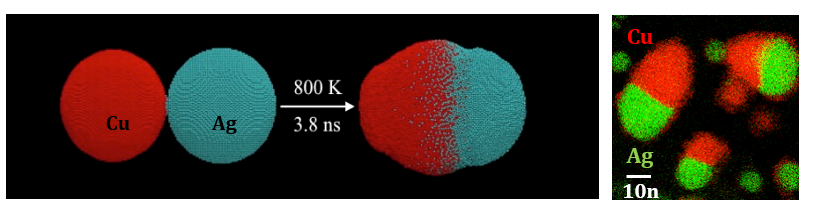

Sandia’s nanosolder begins with a mixture of copper and silver nanoparticles in a toluene-based vehicle, that when heated to 150°C forms a 3-D epitaxial copper core and silver shell structure. The silver shell acts as a protective coating, creating a solder that remains stable when in contact with air until the melting step occurs to form the joint. This approach eliminates the need for specialized equipment to inert the environment. Unlike traditional lead-free solders, the finer structure of our nanosolder permits lower reflow processing temperatures, resulting in less thermal stress during processing. Sandia’s nanosolder can enable further miniaturization of electronics by enabling the development of a broader range of products without the risk of thermal damage to heat sensitive materials and components.

- Low processing temperatures – energy savings

- Easy-to-use

- Compatible with current soldering equipment

- Reduces thermal stresses on heat sensitive materials and assemblies during processing

- Micro-electrical mechanical systems (MEMS)

- Joining of carbon nanotube and additive manufactured materials and parts

- Assembly of complex sensors and opto-electronic products

SD#12758

Published1/31/2017

Last Updated1/31/2017