The Sandia Cooler

Sandia researchers have developed a radically new architecture for air-cooled heat exchangers

In conventional “fan-plus-finned-heat-sink” air-cooled heat exchangers, the primary physical limitation to performance (i.e. achieving low thermal resistance) is the boundary layer of motionless air that adheres to and envelops all surfaces of the heat exchanger. Within this boundary layer region of “dead air”, diffusive transport is the dominant mechanism for heat transfer. The resulting thermal bottleneck largely determines the thermal resistance of the heat exchanger. Another longstanding problem is inevitable fouling of the heat exchanger surface over time by particulate matter and other airborne contaminants. Heat sink fouling is especially important in applications where little or no preventative maintenance is typically practiced. The third major obstacle concerns inadequate airflow to heat exchanger resulting from restrictions on fan noise. Small and medium-sized fans have relatively poor mechanical efficiency; unproductive expenditure of mechanical work on the surrounding air results in high noise levels.

The “Sandia Cooler” architecture simultaneously eliminates all three of the drawbacks of conventional air-cooled heat exchanger technology. The “Sandia Cooler” provides a several-fold reduction in boundary layer thickness, intrinsic immunity to heat sink fouling, and drastic reductions in noise. It is also expected to be very practical from the standpoint of cost, complexity, ruggedness, etc.

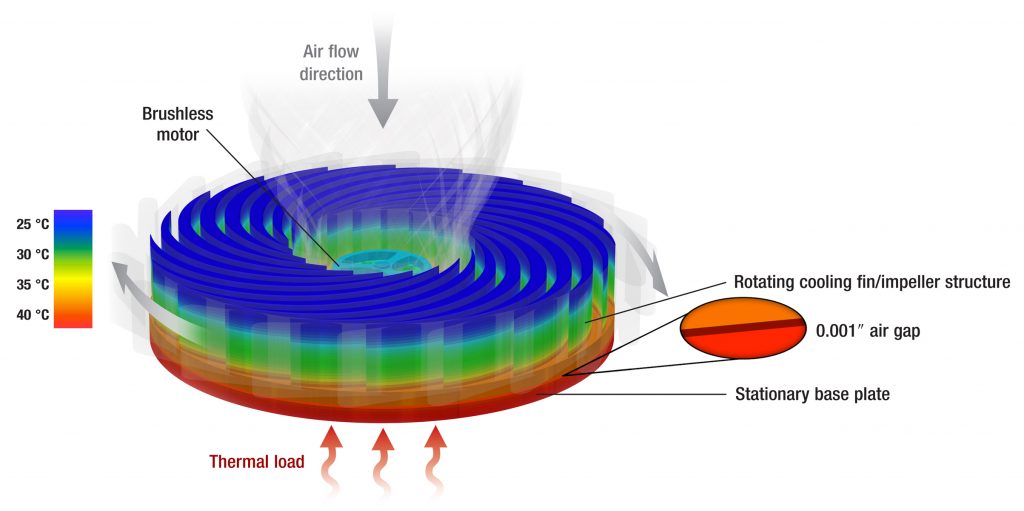

In this new device architecture, heat is efficiently transferred from a stationary base plate to a rotating (counterclockwise) structure that combines the functionality of cooling fins with a centrifugal impeller. Dead air enveloping the cooling fins is subjected to a powerful centrifugal pumping effect, providing a 10x reduction in boundary layer thickness at a speed of a few thousand rpm. Additionally, high-speed rotation completely eliminates the problem of heat exchanger fouling. The “direct drive advantage”, in which relative motion between the cooling fins and ambient air is created by rotating the heat exchanger, provides a drastic improvement in aerodynamic efficiency. This translates to an extremely quiet operation. The benefits have been quantified on a proof-of-concept prototype.

- Dramatic increase in cooling performance without resorting to exotic methods

- Exceptionally quiet operation

- Immune to dust fouling

- Simple, rugged, and cost-competitive design

- Provides increased energy efficiency

- Various other electronic devices

- LED Lighting

- HVAC

- Automotive

- Large Appliances

- Any device comprising one or more forced-air exchangers

- Sandia’s “Cooler” technology offers fundamental breakthrough in heat transfer for microelectronics, other cooling applications Sandia National Laboratories media release (July 2011)

- Sandia Cooler Tech Briefs

- Jeffrey P. Koplow. (2009, September). “A Fundamentally New Approach to Air-Cooled Heat Exchangers.” Prepared by Sandia National Laboratories Albuquerque, New Mexico 87185 and Livermore, California 94550. SAND2009-135192.

| Patent Title | Patent Number | Grant Date |

|---|---|---|

| Axial flow heat exchanger devices and methods for heat transfer using axial flow devices | 10,132,574 | 11/20/2018 |

| Axial flow heat exchanger devices and methods for heat transfer using axial flow devices | 9,261,100 | 02/16/2016 |

| Heat exchanger device and method for heat removal or transfer | 9,207,023 | 12/08/2015 |

| Heat exchanger device and method for heat removal or transfer | 8,988,881 | 03/24/2015 |

| Heat exchanger device and method for heat removal or transfer | 8,228,675 | 07/24/2012 |

SD#10948

Published9/29/2011

Last Updated1/15/2025