Wear-Resistant Platinum Gold Alloy

From cell phones to satellites, industry spends millions on traditional gold alloy electrical contact coatings

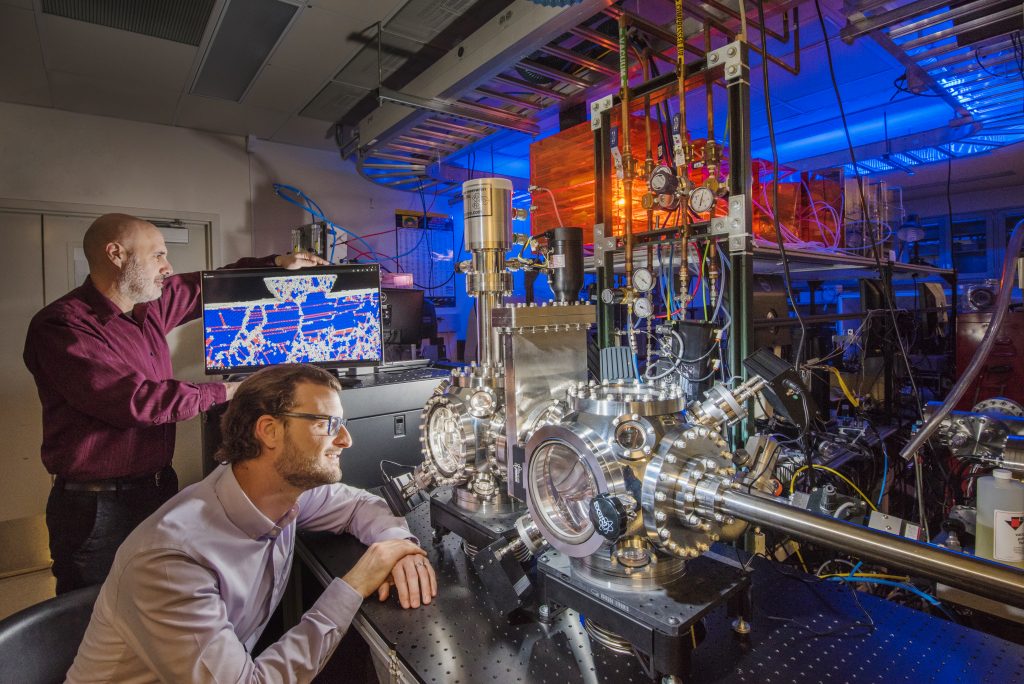

While gold and other metal alloys have been an industry standard to protect metal components from wear due to metal on metal contact, they still experience deterioration over time. Using a novel synthesis approach, Sandia researchers developed an ultra wear-resistant platinum gold (Pt-Au) alloy that can replace gold alloys for improved durability, longevity, and reduced costs in electronic devices.

It has long been thought that metals with smaller grains are harder, and that harder metals wear more slowly. The present work challenges this conception, showing dramatic improvements in wear resistance by mitigating grain growth. Sandia has shown that Pt-Au, one example of a broad, new class of alloys, is able to resist changes in grain structure at remarkably high stresses and temperatures. Sandia’s Pt-Au alloy has demonstrated 100x higher wear life than conventional coatings with superior electrical conductivity. With demonstrated stability at high temperatures (~500°C) and a remarkable resistance to fatigue damage, these alloys can reduce device manufacturing constraints, allowing for non-incremental improvements in the life of electrical contacts. These improvements allow for the reduction of coating thickness resulting from the unparalleled wear resistance, leading to a reduction of material costs. This alloy can be applied using a number of conventional deposition methods, allowing for widespread application in the coatings industry. Sandia’s wear-resistant Pt-Au alloy can be a cost-effective investment over time for industries seeking superior durability and protection against wear. While originally developed for electronic coatings, this alloy also has potential applications in tribological coatings due to its ability to produce a diamond-like carbon lubricant in service conditions.

- 100x more durable that traditional contact coatings

- Easy to apply using conventional deposition methods

- Stable at high temperatures (~500°C)

- Self-healing in anoxic environments—enables formation of aa diamond-like carbon lubricant

- Consumer electronics

- Electronics for harsh environments

- Tribological coatings

- Most wear-resistant metal alloy in the world engineered at Sandia National Laboratories

Sandia National Laboratories media release, August 16, 2018 - R&D 100 Special Recognition 2019

| Patent Title | Patent Number | Grant Date |

|---|---|---|

| Stable nanocrystalline metal alloy coatings with ultra-low wear | 10,763,000 | 09/01/2020 |

SD#14332

Published12/19/2018

Last Updated12/19/2018