Void-Free Electrodeposition of Copper TSVs using Automated Endpoint Detection

Sandia’s endpoint detection method for the electrodeposition of copper through silicon vias (TSVs) could dramatically improve microelectronics manufacturing by increasing throughput and reducing consumables

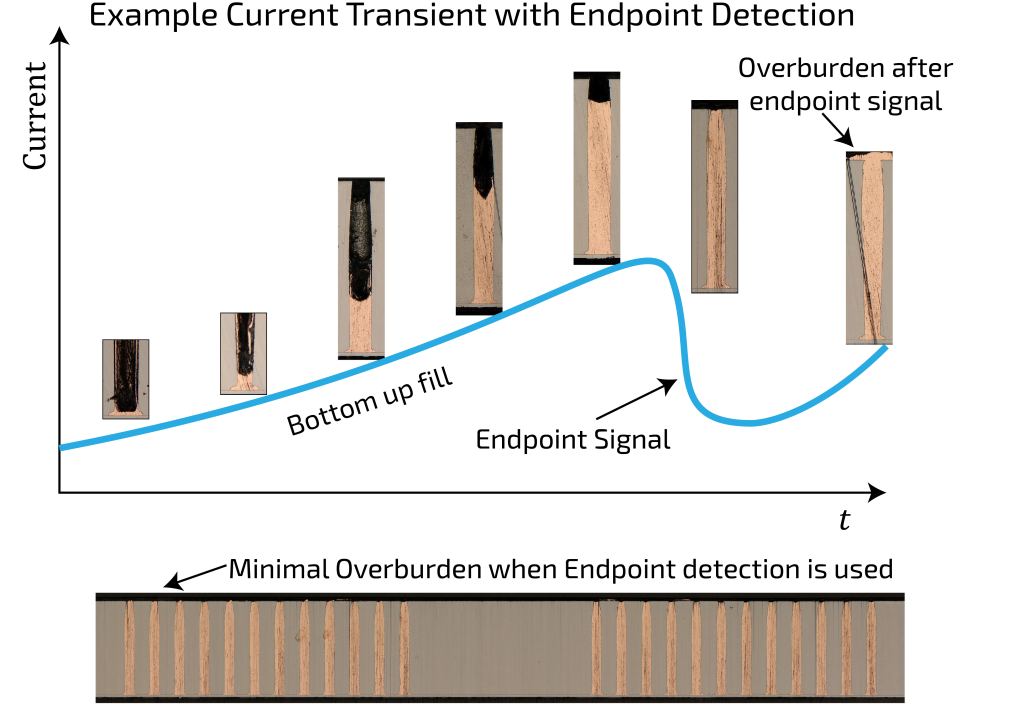

Through-silicon vias (TSVs) provide electrical and thermal interconnection from the front of a semiconductor chip to the back and thus are a key component of high-performance 3D integrated circuits. The void-free electrical connection is formed utilizing an electroplating technique that results in extraneous metal deposition at the surface (overburden) that must be

removed by chemical mechanical polish (CMP). The thicker the overburden, the longer the CMP steps resulting in a loss of throughput and a higher consumption of consumable chemistries and polishing pads.

Sandia researchers have developed a controlled process for bottom-up, void-free electrodeposition-based filling of copper TSVs that includes an automated method for detecting

when filling is completed. The endpoint detection method is based on in situ monitoring of copper deposition through characteristics in the measured current or voltage that change as deposition proceeds to the top of the TSV feature. Endpoint detection during copper deposition improves overall process control and minimizes the overburden plating at the surface of the wafer.

- Improves manufacturing repeatability

- Improves throughput and decreases consumable costs

- Relatively geometry independent – minimizing set up time for large work-mix manufacturers

- Endpoint signals are relatively insensitive to chemical changes – allowing for improved process marginality to changes in the plating electrolyte over time

- Microelectronics manufacturing

- Electroplating systems

- Diverse heterogeneous integration (HI) applications

SD# 15529

Published11/7/2022