Synthesis of Uniform Magnetic Nanoparticles

Highly uniform magnetic nanoparticles are highly desirable for numerous applications including medical imaging, chemical manufacturing, and development of drugs in the pharmaceutical industry. Currently, achieving nanoparticles with a small size range has been one of the biggest challenges with most techniques relying on controlling the chemical reaction kinetics. Because reaction kinetics are extremely sensitive to temperature and mass, reaction reproducibility becomes exceedingly difficult. Besides this, particles produced with this method still often have a large size range, making them unsuitable for many applications which require a high level of accuracy (i.e. a narrow size distribution).

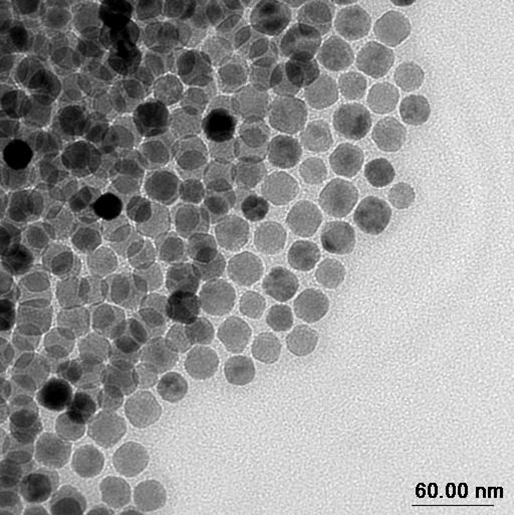

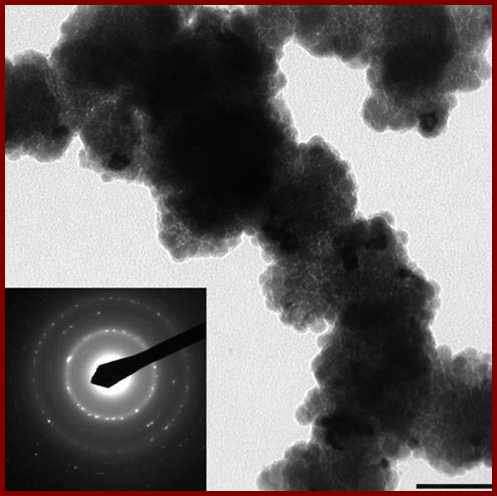

Sandia has developed a novel technique for controlling the size of magnetic nanoparticles that does not rely on conventional kinetic control of the reaction. This technology relies on particle agglomeration and precipitation from solution at a certain particle size. The nanoparticle size is totally dependent upon the size of the surfactant used and/or the reaction temperature. Nanoparticle growth is halted by magnetic agglomeration, as agglomerated particles are unavailable to undergo further reaction. Because of this, this method can be tailored to fit almost any application which requires uniform nanoparticles.

- Highly reproducible reactions:Surfactant size, not reaction kinetics, limit particle size

- Extremely small size range: Particles are agglomerated andprecipitated upon reachingcritical size

- Continuous Process Reactor:Particles precipitate upon reaching critical size

- Chemical Manufacturing

- Health Care Industry

- Pharmaceutical Industry

SD#11088

Published8/3/2012

Last Updated1/29/2013