PC Board Mountable Corrosion Sensors

Sensors to identify and assess the pervasive and expensive problem of corrosion in applications ranging from construction to microelectronics.

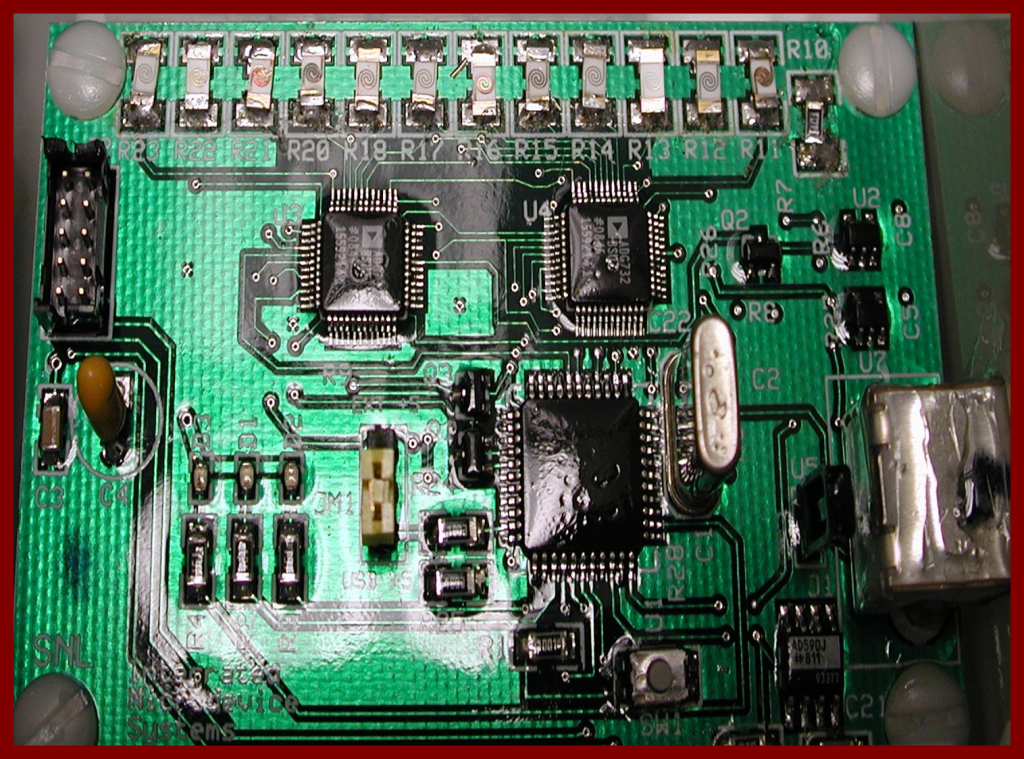

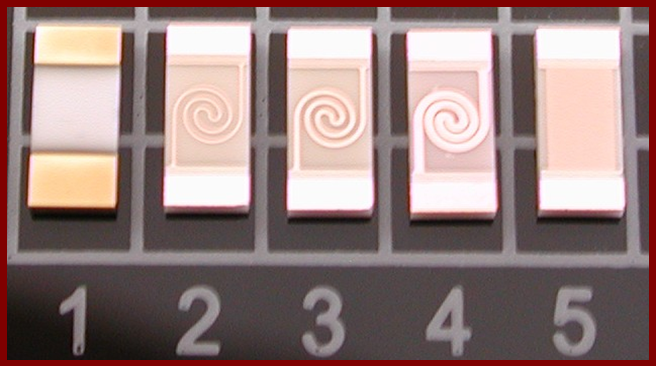

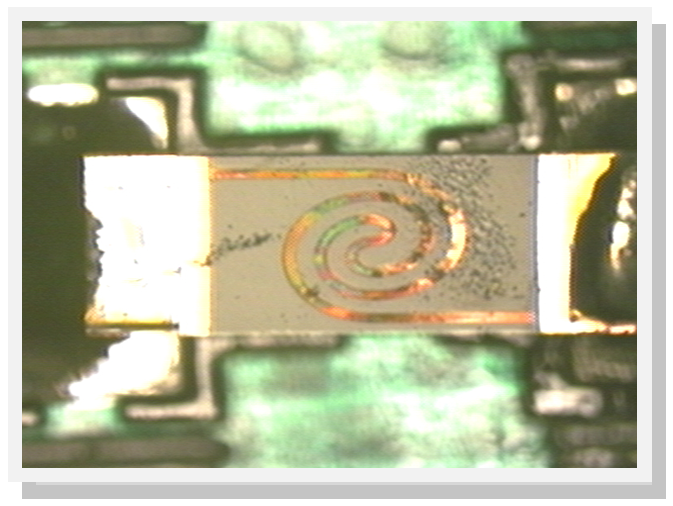

Sandia’s micro sensors are designed and fabricated in the style of standard surface mount components (such as resistors and capacitors), which can be soldered directly onto networks such as printed circuit boards (PCBs). This allows easy integration with support electronics via standard assembly processes in a very small footprint. Corrosive environments passively and proportionately modify a sensor’s response over time allowing periodic interrogation to provide information on the enclosed systems. Sensors can be packaged with a high density for redundancy, designed for a wide range of sensitivity, and strategically located for multiple sensing tasks. The sensors are produced by the hundreds per wafer using standard industry methods resulting in low per unit costs. To date, sensors have been designed for corrosion assessment of copper, aluminum and wire bonded chips. Many other interrogation systems are possible.

- Accumulates corrosion effects passively: power needed only when interrogating

- Designed and fabricated in the style of standard surface mount components which can be directly soldered onto networks such as printed circuit boards (PCBs)

- Sensors can be packaged with a high density for redundancy, designed for a wide range of sensitivity and strategically located for multiple sensing tasks

- Produced using standard industry methods

- Low per unit cost– 600 sensors from a single 4” wafer

- Building Ventilation Systems

- First Responder Respirators

- Household Electronics

- High Consequence Systems

- Water Monitoring Systems

- Architectural Structures

- Automotive Systems

- Space Systems

- Environmental Change Indicators

- Remote-based Systems

SD#11831

Published10/7/2013

Last Updated3/25/2016