Green Extraction of Rare Earth Elements from Coal Waste

A new method converts coal waste into a domestic source of rare earth elements with significantly improved environment, health, and safety outcomes over existing methods

Current methods of mining and separating rare earth elements are not only expensive and labor intensive, they also take a devastating toll on the environment. As demand continues to increase, a secure, reliable, and sustainable domestic supply of rare earth elements from alternate sources is essential for the energy and electronics industries. Sometimes referred to as lanthanides, REEs are a subset of 17 elements with unique properties needed to produce materials such as metals, glass, magnets, catalysts, high-performance alloys, and electronic displays for high-tech components and devices. In 2019, the U.S. imported nearly its entire supply of REEs for a total estimated value of $160 million. Import reliance creates dependencies on foreign sources, poses supply chain risks, and may constrain potential high-growth sectors. More efficient REE extraction methods with low or no environmental footprint are needed to relieve import reliance and secure a domestic supply of this strategically important resource.

REEs are present in a range of sources, including secondary waste streams, yet remain difficult

to isolate because of their tendency to form mixtures. Extraction is a highly complex process that can vary significantly between material types and even individual deposits. In traditional mining processes, initial physical separation consumes a high volume of raw materials and produces significant amount of waste in the form of tailings. Follow-up processing to extract the desired metals from mineral concentrates typically requires industrial-grade chemicals and solvents. The resulting hazardous liquid wastes, radionuclides, and heavy metal residues must be carefully managed according to environmental and occupational health standards, adding significant risk and increased costs.

Sandia’s Approach: Supercritical CO2 and Citric Acid

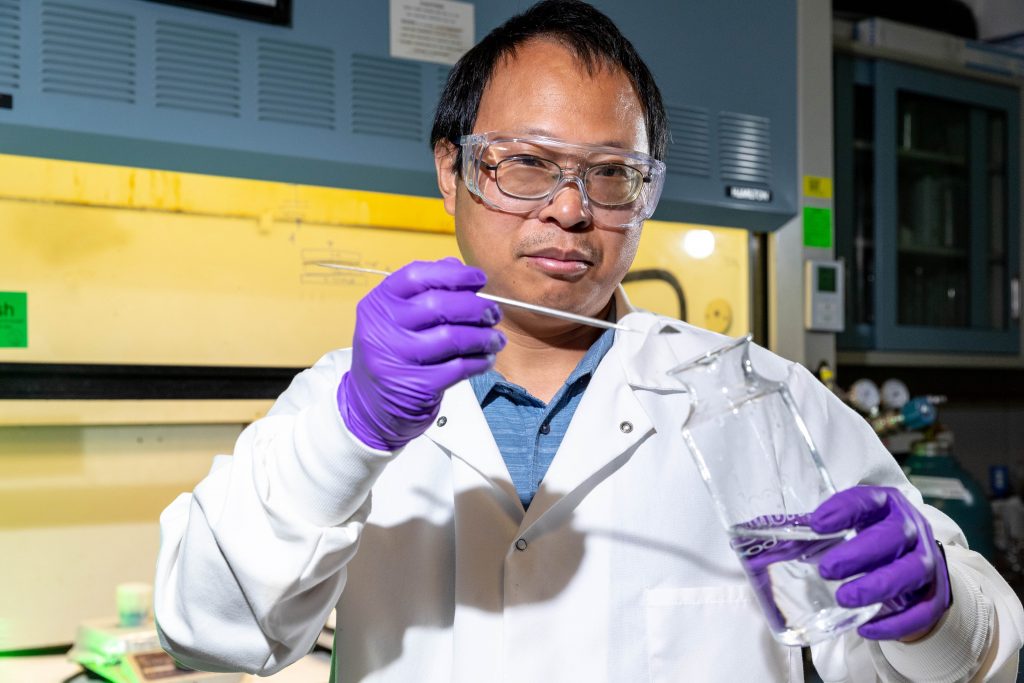

Sandia researchers have developed a groundbreaking approach for converting coal ash, a by-product of coal combustion, into a viable domestic source of rare earth elements using just three readily available ingredients: water, supercritical carbon dioxide (scCO2), and food grade citric acid. By combining thermodynamic and DFT modeling and experimental tests, researchers were able to successfully remove target metals from coal and coal ash using these environmentally benign ingredients. The method has been shown to achieve a 42% extraction efficiency and can preferentially extract some of the most critical REEs. In addition to recovering REEs, this method can also remove other heavy metals from coal and coal ash to make cleaner coal before combustion or cleaner coal ash to facilitate its reuse or final disposal.

- Converts coal industry waste into a reliable domestic source of REEs

- Provides 2x the value of conventional sources and approaches ($ value / mass)

- Environmentally benign

- Provides a greener, lower cost, and domestic REE source

- Recycling and cleaning of coal ash and/or coal combustion residuals

- Mining and extraction of rare earth elements (REEs)

- Recycling of other waste sources for extraction of REE

- Environmentally hazardous coal waste diminished by citric acid

Sandia National Laboratories media release (Oct. 25, 2021)

SD 15352

Published10/19/2021

Last Updated10/19/2021