TufFoam

Rigid Polyurethane Foam

Absorbs Energy, Worker Safe, and Environment Friendly

TufFoam is a toluene diisocyanate (TDI)-free, CFC-free water-blown, closed-cell, rigid polyurethane foam available in densities from 2 to 40 pounds per cubic foot. Initially formulated as an electronics encapsulant to mitigate the effects of harsh mechanical environments, TufFoam can also be used as a structural material as well as a thermal and electrical insulating material.

Absorbs Energy

TufFoam does not fracture or spall upon compression testing even to high strains, where other foams fail at relatively low strains. Other mechanical properties of TufFoam have been found to be comparable or superior to conventional TDI-based foams.

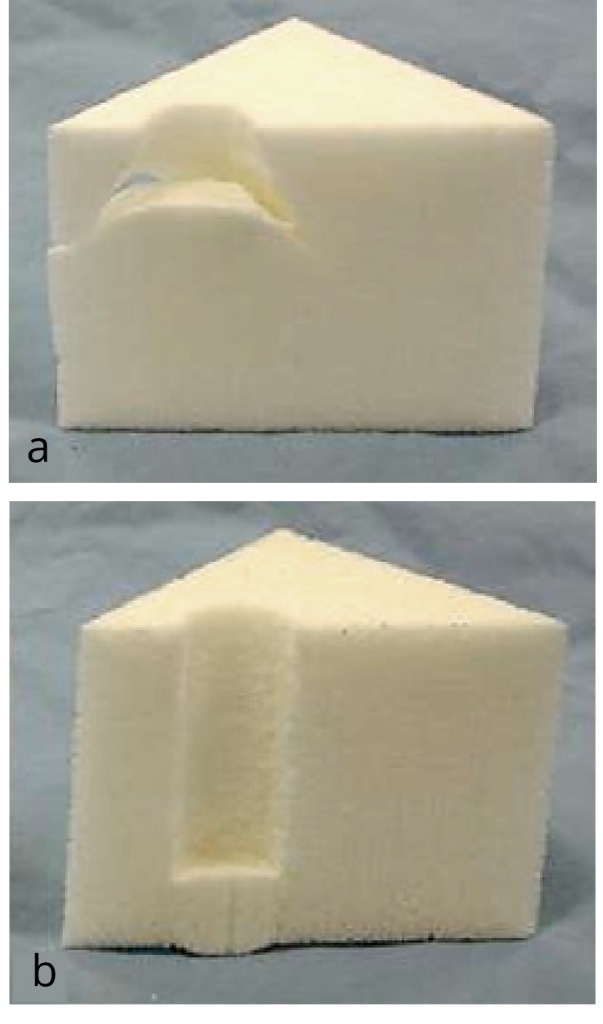

At right: Samples of TufFoam™ (a) and a TDI based foam (b) after being impacted with a plunger showing how TufFoam™ is much more effective in spreading a penetrating load immediately after impact.

Worker Safe

Because TufFoam contains no carcinogenic toluene diisocyanate (TDI), the handling hazards and chemical sensitization associated with exposure during processing of common, polyurethane foams are greatly reduced. TDI is both a chemical sensitizer and carcinogen with a permissible exposure limit of 0.02 ppm. This low limit requires engineering controls to minimize worker exposure and respirators are recommended. With ever tightening Occupational Safety & Health Administration regulations, it is important to choose wisely in the selection of chemicals for manufacturing processes.

Environment Friendly

Water was chosen as the blowing agent for TufFoam instead of CFC’s, hydrochlorofluorocarbons,

fluorocarbons or hydrocarbons. These other blowing agents are either bad for the environment or are flammable. Water reacts with excess isocyanate to generate carbon dioxide gas that ultimately expands the foam. Intelligent selection of blowing agents will help when dealing with ever tightening EPA regulations.

Resists Water Absorption

TufFoam ’s closed-cell structure resists water absorption, and it will not swell, crack or split on exposure to water.

Ease of Use

TufFoam can be supplied either as a two-part kit for foaming in place or molded parts, or as board stock. TufFoam , like most polyurethane foams, is stable, inert and resistant to most chemical and solvents. It is easily worked with common tools.

Applications

- Impact energy mitigation

- Thermal insulation

- Flotation device core

| Patent Title | Patent Number | Grant Date |

|---|---|---|

| Method for providing a low density high strength polyurethane foam | 8,466,207 | 06/18/2013 |

SD 10241

Published12/9/2024

Last Updated12/9/2024