Selective Dual Wavelength Olefin Metathesis 3D Printing (SWOMP)

An additive manufacturing method using new resin chemistries and dual wavelength photocuring to rapidly create high-resolution parts with improved strength and durability

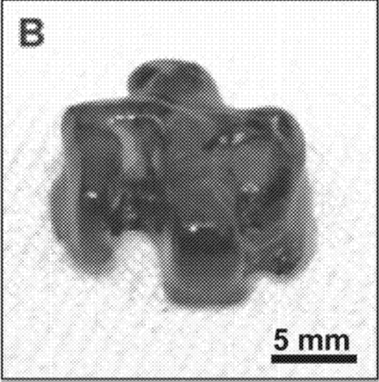

This technique of vat-based 3D printing for robust polymeric materials enables the rapid manufacturing of high resolution, complex geometries at rates 5x faster than conventional stereolithography (SLA) or direct light processing (DLP) printing. This invention enables the creation of custom printed components with applications ranging from automotive, aerospace, membranes, or degradable materials.

Market Need

SLA 3D printing has been a great tool for industrial manufacturing due to its ability to create precise and geometrically complex parts. However, SLA and related methods rely on free radical polymerization (FRP) chemistry, limiting the diversity of material properties. Additionally, time-consuming delamination and recoating steps greatly increase manufacturing time and reduce utility. In addition to being remarkably slow, conventional methods create parts with poor thermomechanical properties that are not suited for industry applications.

Sandia’s Approach

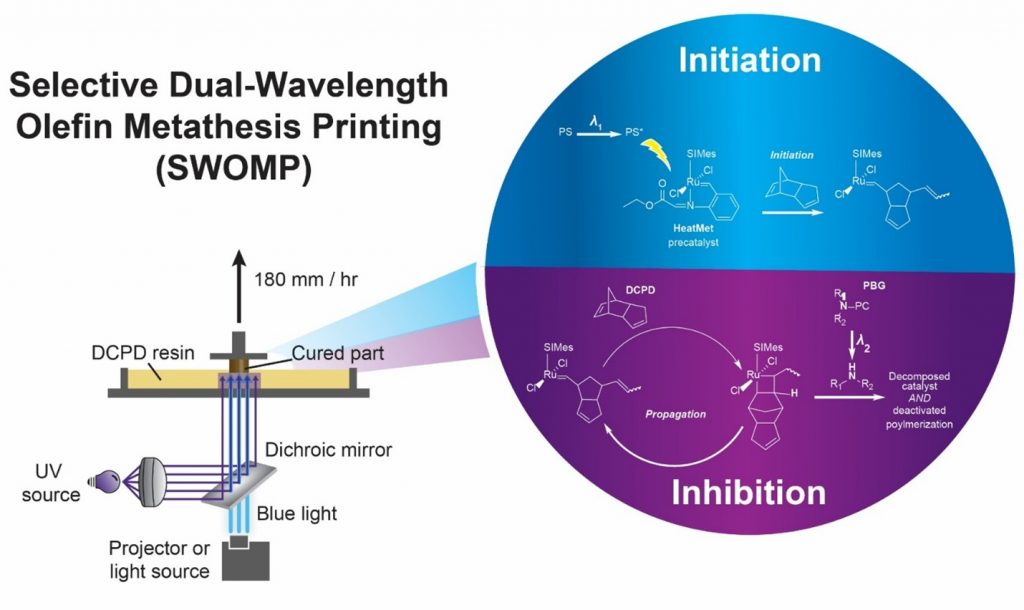

Researchers at Sandia have created a new method of additive manufacturing through a photopolymerization process called SWOMP. This new photopolymerization-based additive manufacturing method uses a first light and wavelength to initiate the ring-opening metathesis polymerization (ROMP) of the metathesis-active monomer, then a second light and wavelength to deactivate the polymerization of the metathesis-active monomer.

This irradiating process cures the photopolymerizable resin to create an object. The cured object then can be continuously withdrawn from a vat of resin to produce a three-dimensional object. The dual-wavelength approach enables volumetric patterning while simultaneously fostering rapid printing speeds. Additionally, SWOMP enables the creation of versatile parts with broad application in multiple industries by using a broad scope of chemistries amenable to polymerization and olefin thermosets with high impact strength, excellent chemical resistance, and thermal properties.

Competitive Advantage

Compared with other photopolymerization 3D printing methods, Sandia’s solution is superior. Industry methods are remarkably slow and conventional resin chemistries result in parts with poor thermomechanical performance. SWOMP address these shortcomings with its novel resin chemistry and dual-wavelength printing method resulting in faster printing and greater thermomechanical properties. Additionally, the inclusion of additives gives better resolution and dissipation of excess heat from the polymerization process.

Next Steps

Sandia is seeking partners to develop and commercialize this technology. To learn more, contact Sandia National Laboratories’ Licensing and Technology Transfer office.

- Novel resin chemistry allowing for photo-orthogonal activation or inhibition of polymerization during 3D printing.

- 5x faster than conventional printing (180 mm hr-1)

- Advanced thermomechanical performance over traditional 3D-printing resins

- Aerospace

- Automotive

- Tooling

- Rapid prototyping

- Other applications requiring rapid iteration of high strength polymer parts

- This work was supported in part by the Sandia Technology Maturation (STM) Program

| Patent Title | Patent Number | Grant Date |

|---|---|---|

| Use of latent metathesis polymerization systems for additive manufacturing | 11,840,586 | 12/12/2023 |

| Use of latent metathesis polymerization systems for photopolymerization-based additive manufacturing | 11,820,839 | 11/21/2023 |

SD 15832

Published2/29/2024

Last Updated2/29/2024