Rapid Electropulsing Method

A rapid electropulsing method to reduce chemical microsegregation in metallic additively manufactured (AM) parts comparable to conventional heat-treatment techniques in a fraction of the processing time

For many applications, the promise of rapid development and fabrication through the additive manufacture (AM) of ready-to-use, geometrically complex parts cannot be realized due to cumbersome thermal post-processing. While AM methods allow for the fabrication of near-net-shape parts, the rapid cooling of each material layer produces microstructures with undesirable features such as chemical microsegregation, residual stresses, and/or equiaxed grains with random textures. Post-build heat treatments are typically used to address these effects; however, thermally treating metallic AM parts has significant downsides such as part distortion, damage, and increased processing times.

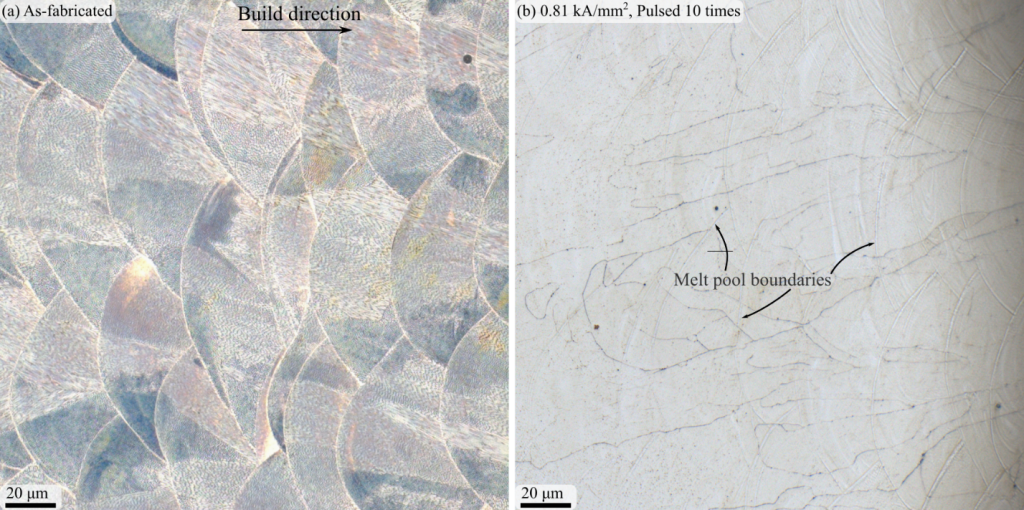

Sandia researchers have developed a rapid method to reduce chemical microsegregation in metallic AM parts comparable to conventional heat-treatment techniques in a fraction of the processing time using short, high-current density electrical pulses (electropulsing). Electrical pulses were passed through 316L stainless steel and aluminum silicon magnesium (AlSiMg) parts fabricated by SLM using a Gleeble® 3500. For stainless steel parts, electropulsing significantly reduced the chemical microsegregation in the as-fabricated part after 10 pulses without significantly altering hardness. Total processing time for this material was 200 seconds, compared conventional heat treatment at 800° C for 2 hours with reduced part hardness. For aluminum, 100 pulses at a current density of 1.68 kA/mm2 were applied to the part for a total processing time of 1,000 seconds, producing three times greater ductility in the electropulsed part in the as-fabricated condition.

- 10x faster processing of stainless steel SLM parts with similar results as conventional heat-treatment

- Enables target modification of a small area, rather than the entire part

- Improved efficiency and throughput

- Automotive

- Aerospace

- Rapid prototyping

- Additive manufacturing (AM)

SD# 15154

Published2/24/2020

Last Updated2/24/2020