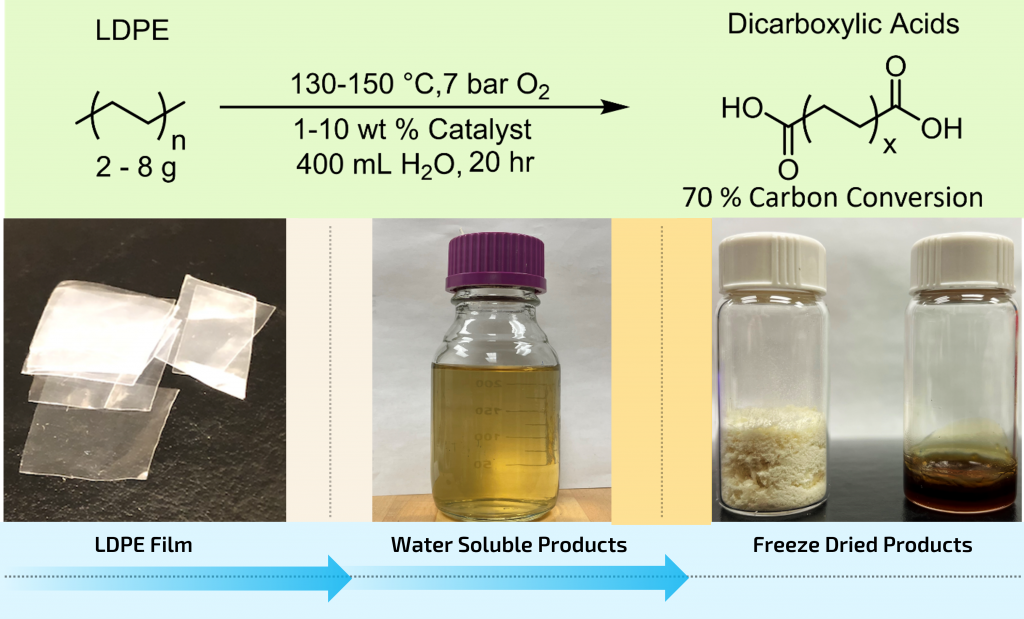

New Method to Convert LDPE Plastic Waste to Useful Chemicals

Degrade plastic waste materials to valuable chemicals, food sources and renewable energy related products using a catalytic oxidative process

Transforming plastic waste to value-added components such as fuels, chemicals, or intermediates has tremendous environmental impact. Depending on the polymer structure of the plastic materials, plastic wastes can take hundreds of years to decompose. This leads to large accumulations of plastic materials in the environment affecting the ecosystem in general. The disruption has the potential to cause a huge deficit in our own food supply and is already impacting wildlife food sources and habitats. Considering these harmful impacts, it’s imperative to find solutions to effectively decompose and reuse plastic waste materials. Few methods have been developed to tackle this issue, and those approaches are limited by their lack of cost effective depolymerization methods and low bioconversion or chemical conversion of the breakdown products.

To reduce the accumulation of plastic waste materials in the environment, Sandia researchers have developed a catalytic oxidative process that can efficiently cleave the strong polymer bonds to degrade plastics. The process needs pressurized oxygen up to 120 psi yet functions in 130-150°C. The developed method was used to depolymerize a commercial Low-Density Polyethylene (LDPE) film using several different catalysts. The depolymerized products were then tested for biological growth and conversion, as well as chemical conversions to oleochemicals, polyesters, and aviation fuel. The catalysts are used to depolymerize the LDPE polymer film and by using size exclusion chromatography analytical instruments, the peak molecular weights of the water-soluble depolymerized products are measured to be below 1000 g/mol for each catalyst. No higher molecular weight material has been detected in those breakdown products. High performance liquid chromatography mass spectrometry data has shown that the breakdown units are relatively small (ranging from 118-249 g/mol) when certain catalysts are used. Thus, this approach has been proven quite effective in taking the right step towards eradicating plastic waste materials from the environment.

- Cost-effective depolymerization method with use of lower temperatures (up to 20° less)

- High chemical conversion of breakdown products from plastics in water

- Use of benign and bioavailable catalysts

- Catalyzed derived oxidative process to break strong polymer bonds

- Generated water-soluble units can easily dissolve in the environment

- Chemical, biochemical, and polymer industry

- Aviation fuel production

- Renewable Energy Industry

- Environmental Protection Agency

SD 16340, 16166, 16095

Published12/15/2023