Multilayered and Programmable Electromagnetic Coils for Microfluidic Devices

An automated and multilayered PCB for microfluidic immunoassays that enables multi-sample testing and portability for clinical point-of-care applications

Microfluidic devices are integrated into all manner of diagnostic or medical devices for reliable technical analysis of biological samples. Although microfluidic devices have gained recognition in the biomedical field in recent decades, establishing an efficient screening platform remains challenging due to the lack of energy and component efficiency in clinical settings.

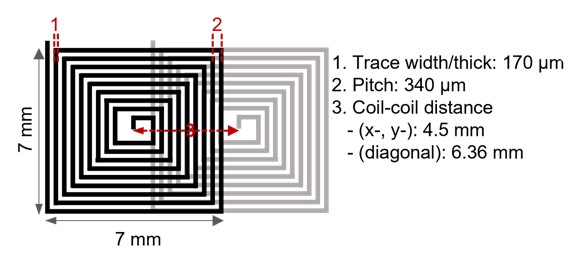

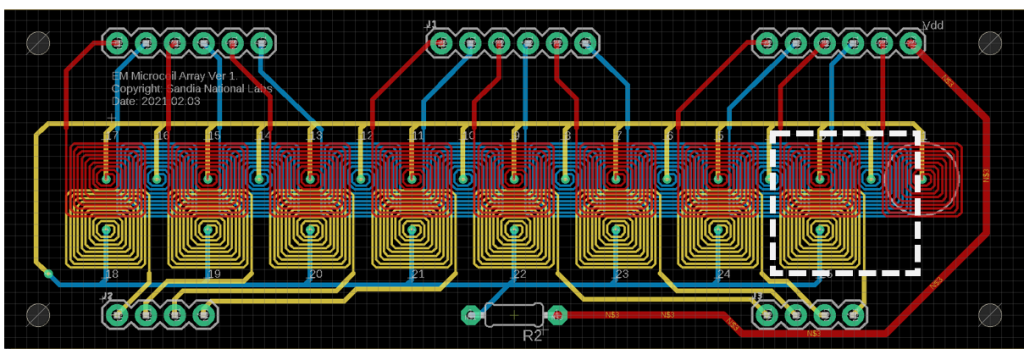

Sandia researchers have developed an automated and multilayered planar circuit board for microfluidic assays. The innovation uses the movement of magnetic beads to transport and process biological samples before measurement. This technology is the first known planar circuit board (PCB) with a long-range 2D transport system created by aligning three overlapping layers of magnetic coil and a programmable controller to direct the electromagnetic field. Compared to existing PCBs, the arrangement of the magnetic coil provides advantages such as reduced power needs for long-range transport of magnetic beads from the permanent magnet. The size and width of the multiplanar electromagnetic array can be modified as needed to fit into the internal microfluidic cassette. An easy-to-use programmable controller controls the movements of beads and liquid droplets, automating the sample process via the magnetic chip/beads within the microfluidic device. In addition to performing immunoassays, the device can be applied for other fit-for-purpose assays using customized magnetic beads and compatible microfluidic devices. The technology allows low detection limits and high sensitivity, rivaling plate-based assays. It also automates steps for a typical sandwich enzyme-linked immunosorbent assay (ELISA), minimizing manual intervention for analyzing biological samples.

- Improved time and energy efficiency, i.e. 8 samples in 45 minutes with <2.5W for bead movement

- High sensitivity and low sample detection limit

- Reduced signal-to-noise ratio

- ~10pg/mL sample depending on types and binding affinitiy of antibodies

- Can be selectively modified to fit into existing microfluidic platforms for DNA, RNA, or other bio-macromolecules

- Biotechnology

- Pharmaceuticals

- Analytical instruments

- Point-of-care medical devices

long range transport system and automated functionalities

SD# 15799

Published12/1/2022

Last Updated1/15/2025