Metal Hydride Nano-Inks

Metal hydride nano-inks for printing electrically conductive, metal-based patterns under ambient conditions that broaden the scope of printable electronic conductors

Metallic inks are useful for flexible displays, smart packaging, environmental and biomedical sensing, energy conversion, and energy storage applications. The most common metallic inks are composed of nanoparticles or molecular precursors that are cured after printing to yield conductive traces; however, most metals are prone to oxidation, especially in the nanoparticle state which limits their utility. The ability to print air-stable, conductive metals is currently restricted to coinage metal nanoparticles such as silver, gold, and copper. Additional nanomaterials are desired by industry to enable novel application areas.

Researchers at Sandia National Laboratories have invented a method for liquid-phase printing of electrically conductive, metal-based patterns under ambient conditions using a stable titanium hydride nanoparticle precursor. This method of using metal hydride nanoparticle inks presents an alternative to traditional metal inks, broadening the scope of printable conductors and adding value to energy, sensing and catalysis applications. In comparison to traditional printed metals, titanium exhibits increased stability to environmental stressors, which makes it useful for electrochemical, biological and high temperature applications.

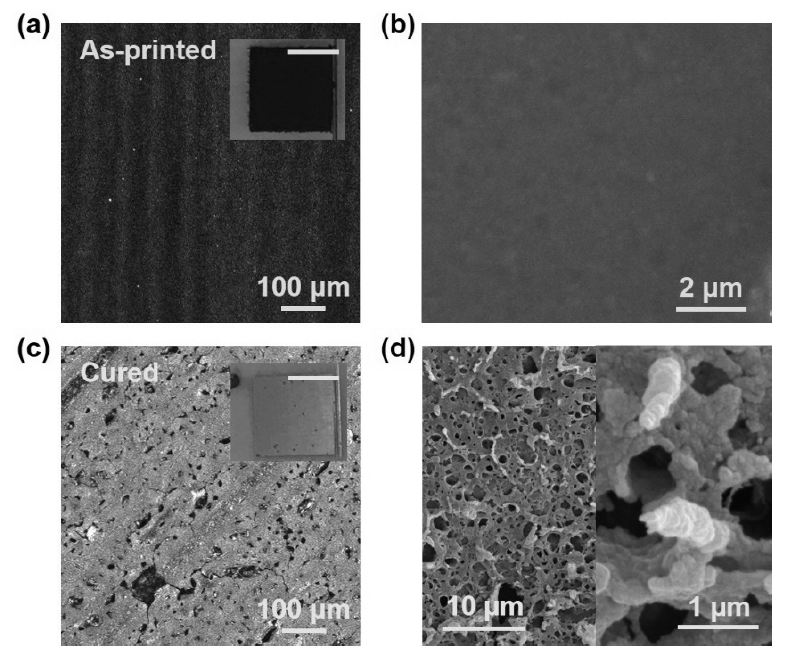

This method can be used to print electrically conductive titanium-based patterns from titanium hydride nanoparticle inks, which has previously been difficult to accomplish. Rather than starting with a highly reactive Ti0 nanoparticles or salts, titanium hydride is stable during post-printing conversions. The printed metal can be converted to a variety of anionic materials such as oxides, nitrides, phosphides, arsenides or sulfides based on the gas exposure during post-processing. Printed patterns on polyimide were found to exhibit electrical conductivity with sheet resistance on the order of ~150. Other metal hydrides are being developed as well.

- Cured titanium hydride sheet resistance: ~150

- Metal hydride nanoparticles < 200 nm in diameter

- Aerosol deposition yields high resolution pattern (20-100 micrometer line width)

- Pulsed photonic curing results in an electrically con

- Printed circuits

- Automotive catalysts

- Sintering applications

- Sports equipment

- Various ceramics

- Thermal spray coatings

SD# 14965.0

Published4/29/2020

Last Updated4/29/2020