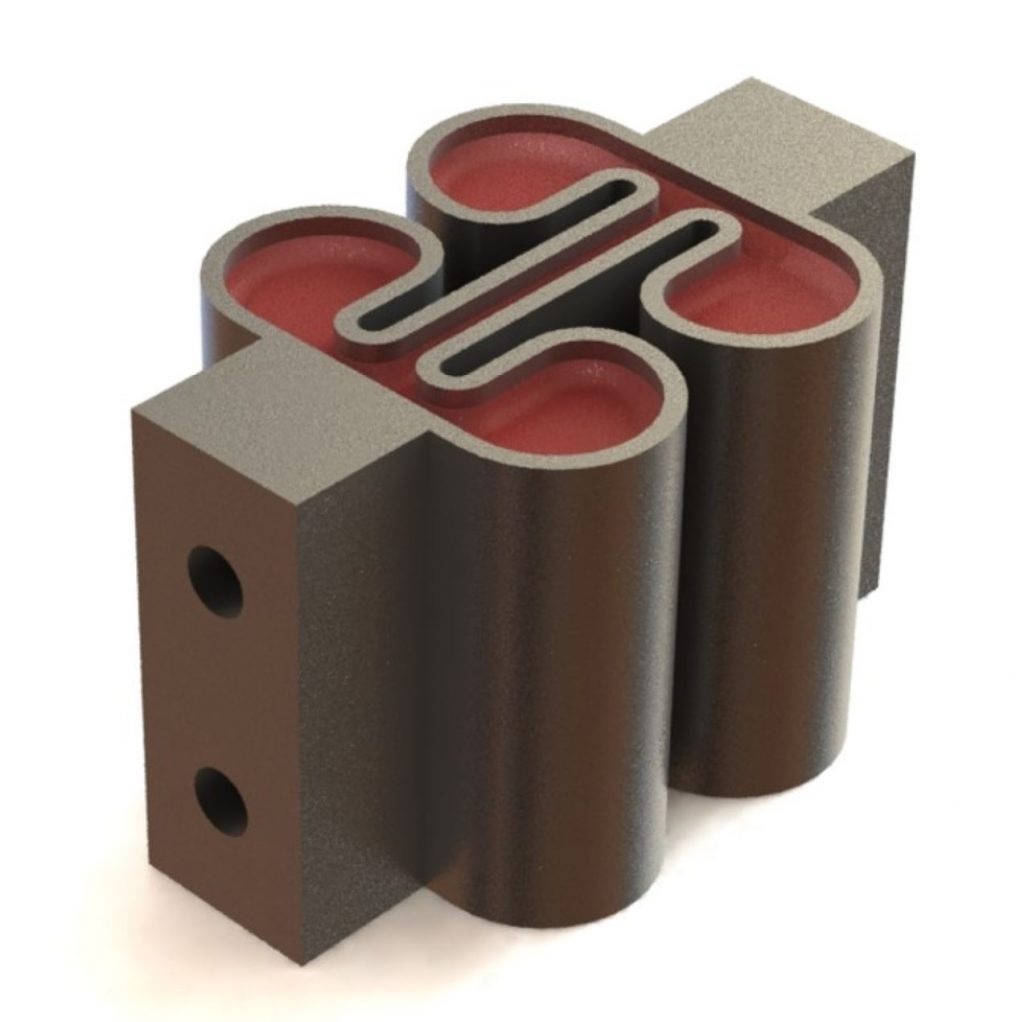

Flexure for Self-Assembly

A compliant flexure design with highly tunable features to reduce error and over-constraint in sophisticated manufacturing and assembly environments

Conventional fasteners like nails, bolts, and welds are subject to manufacturing and inspection tolerances, differential thermal growth, and other sources of error that lead to over-constraint and other challenges for manufacturers and assemblers. Researchers at Sandia National Laboratories have developed a versatile flexure design that resolves common issues such as over-constraint while providing more sophisticated control of freedom of movement, stiffness, configuration, and constraint and compliance features. This level of control and versatility is valuable in advanced or self-assembling manufacturing settings, particularly for large or complex systems.

The flexure design offers compliance in all six degrees of freedom with a hard stop in one degree of freedom after a predetermined range of motion. It has the ability to accomodate a high degree of tunability which can be determined by application. Rigidity and range of motion can be set through tuning of material type, material thickness, and overall weight. The flexure is available in straight arm and curvilinear options and can be configured for use independently, semi-independently, coupled together, or as a set. Its stiffness can be adjusted by changing key geometric dimensions. The flexure may be potted in a visco-elastic material to suppress vibration.

- Reduces or eliminates error in assembly and manufacturing

- Sophisticated control of key flexure features such as range of motion, stiffness, configuration, constraint, and compliance

- Tunable design accommodates a wide range of material types

- Automated or manual control of coupling mechanism

- Optional visco-elastic potting suppresses vibration

- Compatible with 3D printing

- Aerospace

- Automotive

- Autonomous assembly systems

- Panel / beam assembly

- Manufacturing

- Medical devices

Applications and Industries

SD# 14845

Published11/12/2019

Last Updated11/12/2019