Electro 3D: Electrochemical 3D Printing

A new method of additive manufacturing that leverages fluidics and electrochemistry to rapidly produce high-quality parts with engineering materials.

Existing methods of metal 3D printing are ineffective in creating micro-resolution parts of high-quality metals at room temperature and pressure without the need for postprocessing or electrochemical baths.

Market Needs

Additive manufacturing of metal parts remains a primary interest for researchers in the manufacturing industry. The majority of metal 3D printing is accomplished with a thermochemical process, where a metal medium (powder, wire, polymer-metal ink) is melted and fused by a heat source to create a solid object. Thermochemical 3D printing can achieve complex shapes with a variety of alloys. However, there are still technical challenges and market sectors yet to be addressed. For example, machine-to-feedstock variability slows down part qualification. Additionally, fully dense parts require post-processing which limits the ability to precisely control material properties and is very time consuming.

Sandia’s Approach

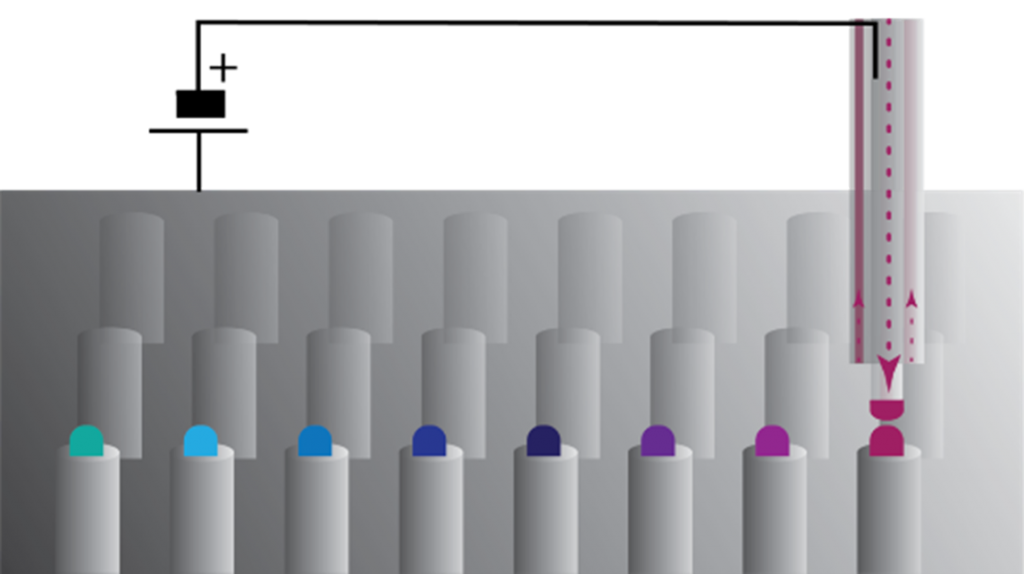

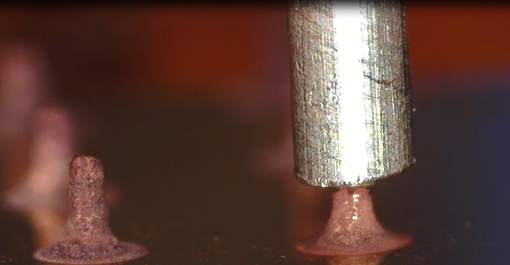

Researchers at Sandia National Laboratories have created a new method of additive manufacturing through an electrochemical process called Electro 3D. This new technology leverages fluidics and electrochemical techniques, placing them in a 3D printing platform that allows for localized and selective deposition of materials at room temperature. Electro 3D revolutionizes electroplating by taking the traditional methods and condensing them into a self-contained 3D printing nozzle where a constantly flowing electrolyte allows for consistent deposition of material. Additionally, because Electro 3D eliminates the step of submerging parts in an electrochemical bath, chemically sensitive substrates can be used as a print bed. This novel technology can produce high-quality and tunable parts at a micro-resolution, while being more energy efficient than traditional thermochemical 3D printing.

Competitive Advantage

Compared with other thermochemical and electrochemical 3D printing methods, Sandia’s solution is superior. Industry thermochemical processes fall short in their ability to print at room temperature and micro-resolution without the need for high thermal post processing.

Similarly, available electrochemical 3D printing methods need a plating bath for the deposition of metal which limits the ability of the user to print on chemically sensitive substrates. Additionally, no industry technology exists that allows for rapid material transition. Electro 3D addresses all of these shortcomings and allows the user to create micro-resolution parts with high-quality material properties at room temperature and pressure without post-processing or a need for electrochemical baths.

- Electro 3D can print a variety of materials such as:

- Metals

- Alloys

- Metal Oxides

- Semiconductors

- Organic Polymers

- Greater Efficiency

- Lower Embodied Energy

- Reduction of CO2 Emissions

- Microscale Resolution

- Aircraft and Aerospace

- Solar Cell manufacturing

- Sensors

- Thermoelectric generators

- Printed electronics

- Microelectronics

- Compound Semiconductor manufacturing

- Compound Semiconductor manufacturing

- Medical and Dental Devices

- Jewelry Design and Fabrication

- Materials discovery

- Marking

SD 15617

Published12/6/2023