Automated Gloving System

Engineers at Sandia Labs have invented the only fully Automated Gloving System to prepare and dispense gloves for quick application while reducing the potential for contact contamination. Dust and particulate matter can cause catastrophic failure in a cleanroom where microelectronics and semiconductors are manufactured. Cleanliness is also essential in a variety of additional industries, such as medical, pharmaceutical, and food service. By making it easier to apply gloves, it encourages personnel to change them more often—significantly reducing the risk of contamination.

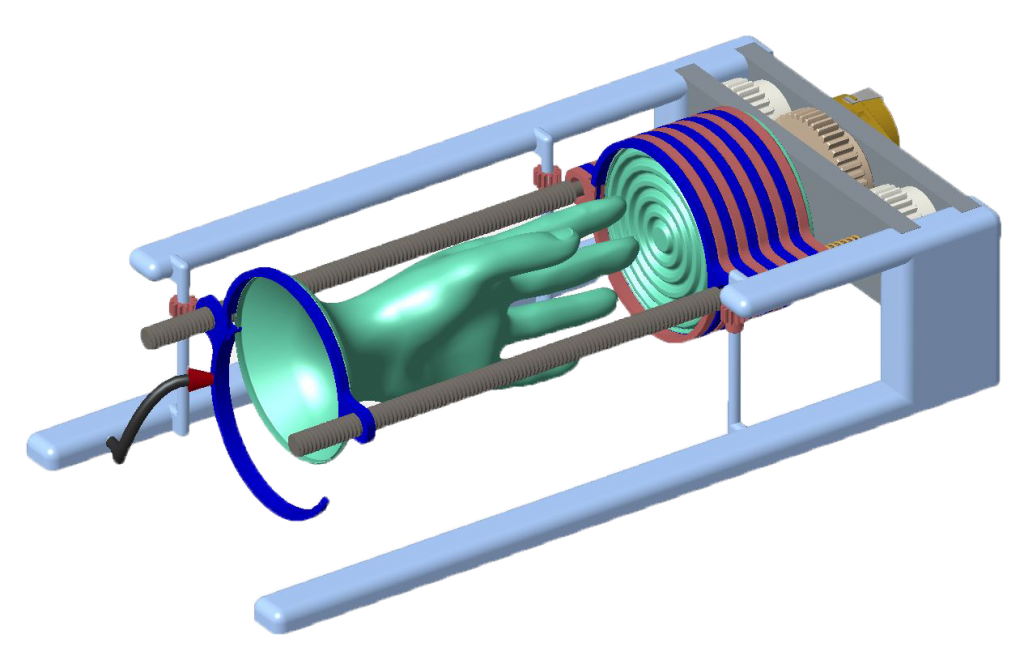

Sandia’s Automated Gloving System is a self-contained system that integrates a simple screw drive and sensors, to quickly and easily dispense and apply gloves. Users simply put their hands into the device’s application openings, triggering a sensor that advances a pair of clean gloves. A jet of air near the application openings partially inflates each glove, allowing users to easily slide their hand into the glove. Once the glove is applied, the user simply pulls their hands down and out of the application openings to release the glove from the cuff. No contact is made to the exterior of the glove during the entire application process, ensuring there is no contact contamination. The system uses specialized gloves with an integrated removable cuff that holds the glove open while transferring it to the application opening. Sandia has also developed a one-step modification that can easily integrate the cuff into current glove manufacturing processes. Our innovative Automated Gloving System can be utilized by various industries in which cleanliness is a key factor.

- Various medical fields including pharmaceuticals

- Cleanroom applications

- Food service

- Quick and easy application

- Reduces potential for contact contamination as exterior of gloves do not need to be touched

- Allows for the donning of multiple pairs of gloves without assistance

SD#14008

Published10/10/2017

Last Updated11/12/2018