Advanced UV Laser Design for Precision Timing and UV Sterilization

Breakthrough laser design offers unmatched accuracy and reliability for applications including precision timing for defense, space exploration, and telecommunications.

Current UV laser technologies face several limitations that hinder their reliability in critical applications. Strain within the laser structure can lead to the formation of cracks that in turn can compromise the structural integrity and degrade laser performance over time. Carrier leakage is another issue that reduces the efficiency of the laser, whereby charge carriers can escape from the quantum well active region and diminish the laser’s output and stability.

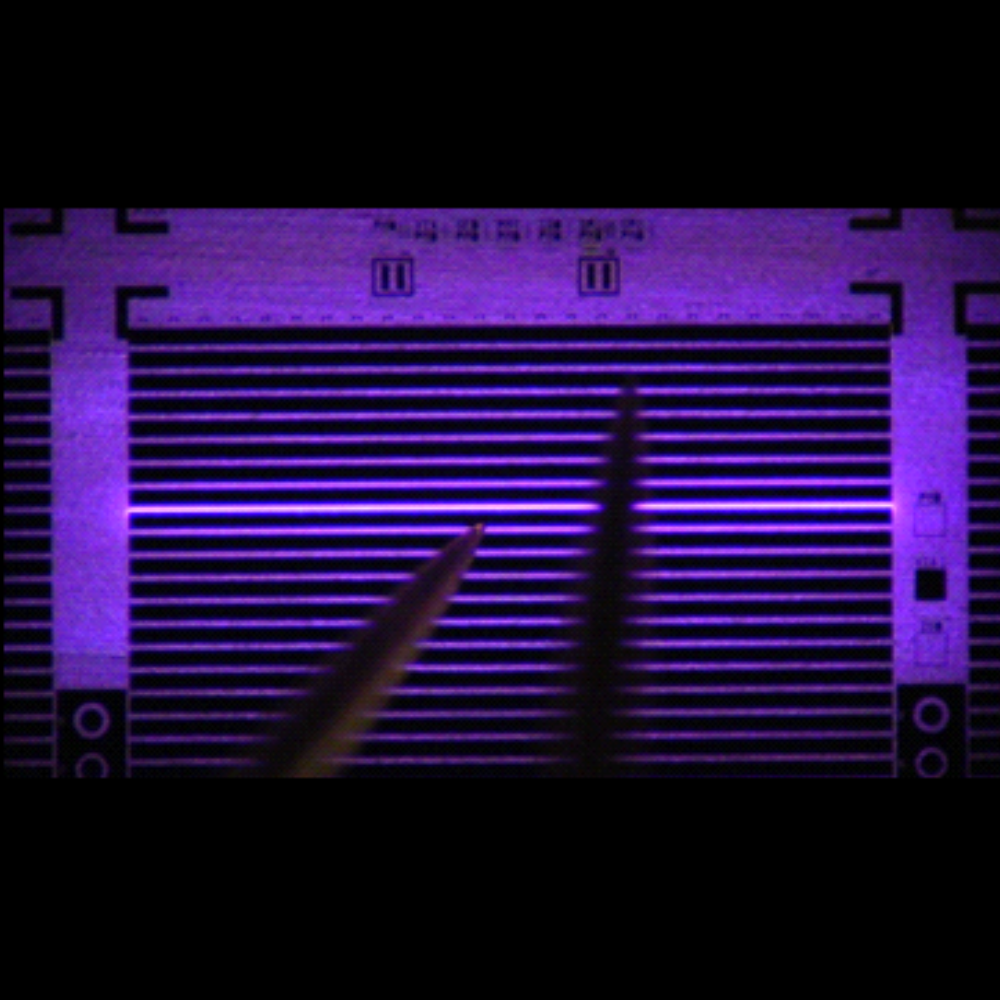

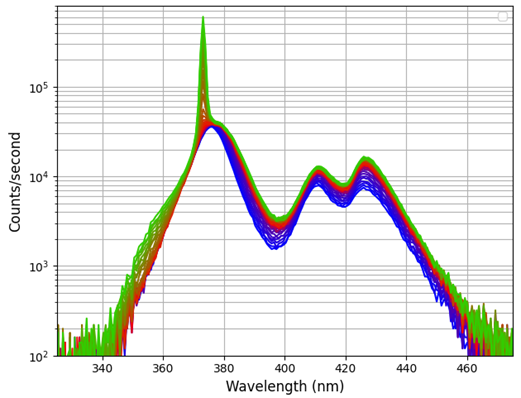

Researchers at Sandia National Laboratories have developed a novel ultraviolet (UV) laser structure operating at 369 nanometers (nm). This innovative design addresses key challenges in traditional UV laser technology and promises significant advancements in precision and operational stability. Sandia’s laser design combines multiple features that offer improved structural integrity, enhanced carrier confinement, and superior operational stability, making it a valuable contribution to the field of UV laser technology. By integrating a quaternary InAlGaN lower cladding layer, an asymmetrical active region, graded hole, electron blocking layers, and a polarization-doped graded InAlGaN p-type cladding layer, the invention addresses key challenges in laser performance and reliability.

UV lasers operating at 369 nm are critical for various applications, including spectroscopy, atomic clocks, and quantum computing. Traditional designs face challenges such as strain-induced cracking, carrier leakage, and parasitic optical feedback, which can degrade a laser’s performance and reliability. While individual features to address these issues have been reported in the literature, their unique combination in the present invention offers a significant advancement in the state of the art.

- Reduced Strain and Cracking: The quaternary InAlGaN lower cladding layer minimizes structural strain, enhancing durability.

- Enhanced Carrier Confinement: Graded hole and electron blocking layers prevent carrier leakage, ensuring optimal performance.

- Improved Hole Injection Efficiency: The polarization-doped graded InAlGaN p-type cladding layer facilitates efficient hole transport.

- Reduced Laser Linewidth: The asymmetrical active region design suppresses refractive index fluctuations, leading to a more stable output.

- The advanced UV laser technology has significant potential in multiple fields:

- Atomic clocks measure time based on the vibration of atoms. They rely on the stability and accuracy of light produced by lasers to conduct this measurement. The improved laser technology is crucial for Yb+ microwave ion clocks, enhancing their accuracy and reliability for defense, telecommunications, and scientific research applications.

SD# 16863

Published6/11/2025

Last Updated6/11/2025