During the COVID-19 pandemic, the long lead times associated with existing testing methods for respiratory personal protective equipment (PPE) significantly hindered the certification process for new manufacturers. This prevented a large volume of available PPE from being validated as effective, reliable, and trustworthy. Consequently, the inability to certify new sources of PPE exacerbated the global shortage, forcing frontline workers, healthcare professionals, and the public to resort to mask reuse or rely on unvalidated and potentially counterfeit masks. Together, these circumstances resulted in increased virus exposure, spread, and mortality.

First responders, healthcare professionals, and the broader public require consistent and reliable access to high-quality respiratory PPE to protect against airborne pathogens, especially during pandemics or crisis situations. A 2023 workshop organized by the National Academies of Sciences, Engineering, and Medicine (NASEM) encompassing respiratory PPE underscored the critical need for a dependable and trustworthy PPE supply at both regional and national scales, which is essential for national security, public health. A strategy to achieve this is to enhance the efficiency of test methods through new and expanded approaches to reduce turnaround times for certification.

Leveraging interdisciplinary expertise in aerosols, materials science, and quantitative assessment, Sandia researchers have designed a suite of expanded approaches for testing and certifying PPE. These testing approaches combine filtration testing and fit testing to remove bottlenecks, reduce costs, and improve safety and effectiveness for end users. They deliver richer data on key performance factors and have the potential to inform future standards development for a more robust and resilient PPE supply chain.

Sandia’s three testing protocols include:

• Gen 1.0 uses an enhanced mask form to test filter media according to existing NIOSH standards.

• Gen 1.5 features an enhanced head form profile, expanded filter test area, and improved negative contour seals to accommodate a variety of respirator types.

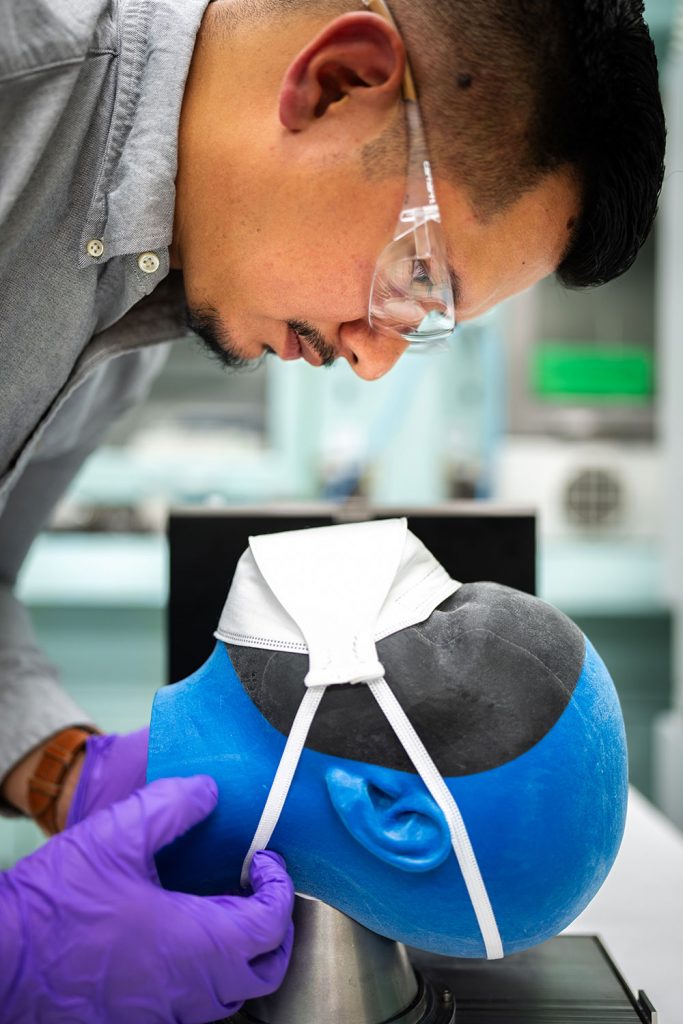

• Gen 2.0 employs a full human head form with the respirator engaged to incorporate nose stay performance and two-material head construction. This holistic testing approach is sensitive to all respirator failures, not just those related to filter media. These advancements aim to provide faster certification times and improved safety for end users. See page 3 for images and additional descriptions of each approach.

See page 3 for images and additional descriptions of each approach.

Existing PPE testing approaches are time consuming, prone to human error, and primarily focus on the performance of the filtration media rather than the complete assembly. Additionally, current methods do not accurately represent actual end use scenarios, which can compromise safety. This approach addresses these limitations by streamlining testing processes, significantly reducing the time required for certification and enabling faster access to reliable PPE.

Sandia is seeking partners to develop and commercialize this technology. For more information, please contact Sandia National Laboratories’ Licensing and Technology Transfer office.

Benefits

Sandia’s comprehensive testing methods provide a rapid, effective, and more comprehensive approach for certifying the effectiveness of respiratory PPE. Not only do they provide richer data on key factors for PPE performance, but they also have the potential to help inform future standards development for a more robust and resilient PPE supply chain.

- Rapid throughput – Test and certify PPE in minutes, not hours

- Comprehensive assessment –Approaches offer combined testing of the filtration media, fit, repetitive use, and full assembly performance

- Reduces bottlenecks in the supply chain

- Cost-effective and scalable methods

- New testing and data may inform future standards development

Applications & Industries

- Emergency response organizations

- Healthcare facilities and hospitals

- Research facilities

- Medical device manufacturers

- Industrial and construction sectors

Recognition