Substitutional Tuning of Metal Hydrides for Hydrogen Compression

An alternative to high-pressure hydrogen compression that can isolate thousands of new metal hydride compositions for hydrogen storage applications

Hydrogen compression is one of the key components of a hydrogen-based economy. Conventional mechanical hydrogen compressors have a few disadvantages including low energy efficiency, insufficient reliability, high operating costs, probability of hydrogen leakages, and significant vibration during operation.

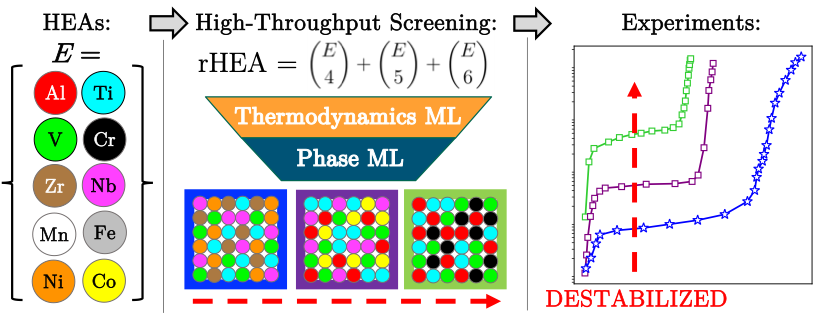

To overcome some of these limitations, Sandia researchers have proposed an alternative approach consisting of a metal hydride thermal (de)sorption compressor. This technology works by reversing the interactions of metal alloys with hydrogen gas to form hydrides. Using a database of metal hydride thermodynamics, a tree-based machine learning (ML) model can be trained to predict the plateau pressure at a given temperature. This explainable ML model provides guidelines to identify thousands of new metal hydride compositions, as well as has the capability to demonstrate the mechanism to increase plateau pressure.

In this technology, a new approach to increase the plateau pressure in interstitial metal hydrides is presented. The method consists of substituting one or more metals in high-entropy alloy hydride to concomitantly tune important properties of the starting composition that predominantly affect the hydrogen equilibrium pressure. The design rules that dictate tuning of these critical properties are extracted from an explainable data-driven modeling approach. The proposed substitutional tuning approach provides clear design rules which are extracted from explainable machine learning (ML) data. This ML-inspired materials design technology can enable isolation of thousands of new metal hydride compositions for hydrogen storage and compression, with tunable thermodynamic properties for targeted applications. The simple design rules explained in this work are broadly consistent across a range of compositions, metal substitutions, and structural classes exhibited by intermetallic hydrides. This approach is particularly useful for substitutional tuning of metal hydrides for high-pressure hydrogen compression. Even more successful hydride compressor materials (higher equilibrium plateau pressures) can be targeted by tuning the design features illustrated by Sandia researchers in this work.

- Simple and clear design rules for high-pressure hydrogen compression

- Machine Learning (ML)-inspired materials design approach

- Isolation of thousands of new metal hydride compositions for hydrogen storage

- Potential for generating more successful hydride compressor materials

- Hydrogen powered vehicles / vehicle manufacturing companies

- Oil and fuel production industries

- Electric vehicle production companies (for hydrogen fuel cells)

- Green gas manufacturing industries

SD 16135

Published6/15/2023

Last Updated1/20/2025