Multifunctional Platelet Composites for Tin Whisker Mitigation

A composite coating with enhanced resistance to whisker penetration and improved thermal conductivity and dielectric properties

In order to comply with the Restriction of Hazardous Substances (RoHS) directive, pure tin is replacing lead-tin alloys in commercial electronic devices. Unfortunately, tin can grow whiskers that can lead to electrical short circuits or metal vapor arcing, both of which threaten the long-term reliability of electronic systems for weapons, satellites, military, and automotive applications and cause critical systems to fail catastrophically. A current method of whisker mitigation utilizes coatings based on both glassy or rubbery unfilled polymers, but such coatings are not impenetrable to tin whiskers.

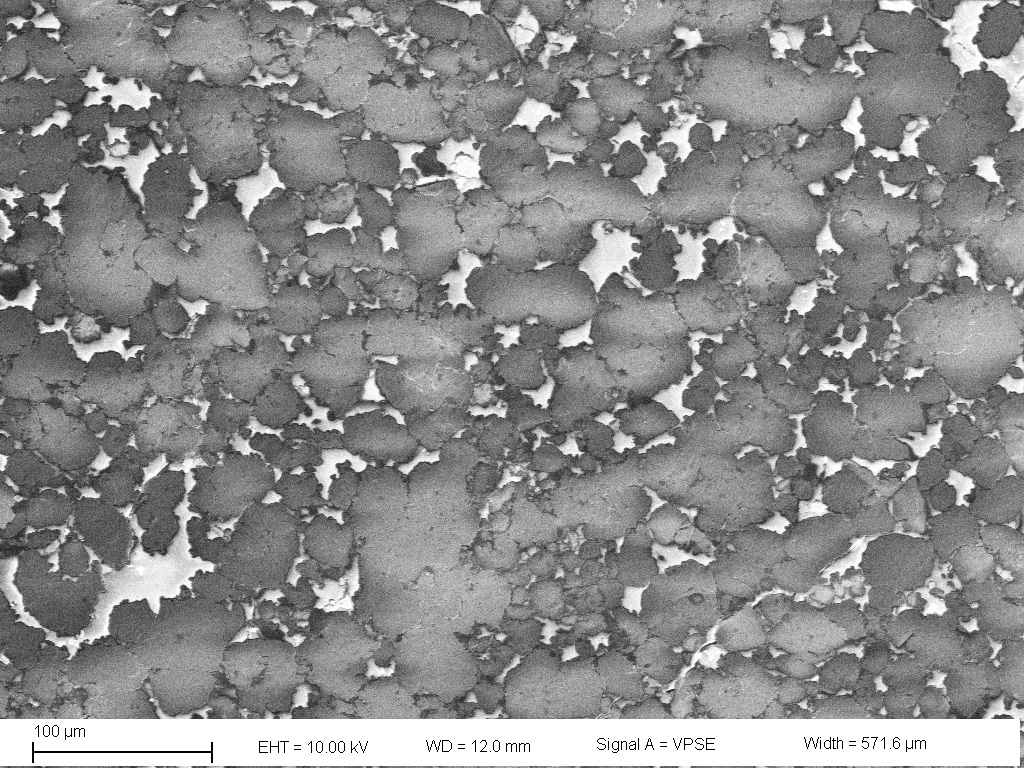

Seeking a more reliable method of whisker mitigation, Sandia researchers developed a composite coating comprised of platelet-shaped particles such as Ni or MgF2 coated Ni/Al dispersed in silicone or epoxy. When the platelets are oriented with their directors normal to the tin-plated surface, they create a multilayer barrier resembling that found in nature (e.g., abalone shell). Platelet orientation is easily controlled using surface modification to prevent the polymer from wetting the platelet surface, extrusion, and applying magnetic or electrical fields. Platelet-filled composites vastly outperform conventional unfilled polymers. In tests conducted in a thermal cycling environment known to promote whisker growth, commercial capacitors coated with the Sandia composite exhibited no signs of whisker penetration, whereas those coated with conventional polymers showed whisker penetration. In addition to its increased penetration resistance, Sandia’s composite enhances thermal conductivity and dielectric properties, and reduces out-of-plane gas permeability.

- Increased reliability of electronic systems

- Proven performance in varied temperatures/humidity

- Easy application methods

- Enhanced thermal conductivity & dielectric properties

- Reduction of out-of-plane gas permeability

- Consumer electronics

- Electronic weapons systems

- Satellites

- Defense

- Automotive

SD#13208

Published1/12/2016

Last Updated1/10/2019