Nanocomposite Anti-Corrosion Coating

A low-cost, environmentally-friendly thin film coating with demonstrated atmospheric corrosion resistance that meets or exceeds conventional coatings 10x as thick

Metals across nearly every industry have a need for high performing, low-cost, environmentally-friendly anti-corrosion surface treatments. Films and coatings have long been used to combat corrosion by physically separating metals from corrosive media or by inhibiting electrochemical reactions that drive corrosion. A new class of layer-by-layer (LbL) nanocomposite thin film barriers has emerged as a promising materials-based solution for a wide range of applications; despite their relative impermeability against molecular transport, a key part of corrosive processes, they have not yet been thoroughly investigated for anticorrosion applications.

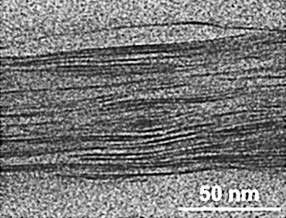

Sandia researchers have developed a high-performing, multilayered barrier coating to protect surface materials from atmospheric and chemical corrosion. Compared to existing materials, this LbL-deposited thin film barrier comprises polymer-clay nanocomposite materials with superior corrosion protection and impermeability imparted by highly-organized clay platelet layers in a functional polymer matrix. Made from inexpensive, environmentally-benign materials, the thin film coating can be deposited conformally on complex shapes, and the coating’s multistep deposition process minimizes through-film defects and allows the incorporation of electrically-insulating clay constituents which further resist corrosion. With demonstrated atmospheric corrosion resistance on par with or better than conventional coatings 10x as thick, this coating represents an effective alternative to costlier, more toxic, and less scalable films for anti-corrosion protection.

• Highly tunable properties

• Diverse surface materials

• Dip-coat or spray application

• Low thickness (nanometer to micrometer thick)

• Reduced manufacturing cost

• Medical devices

• Structural materials

• Decorative

| Patent Title | Patent Number | Grant Date |

|---|---|---|

| Cell-based composite materials with programmed structures and functions | 10,605,705 | 03/31/2020 |

SD# 14225

Published3/11/2020

Last Updated3/11/2020