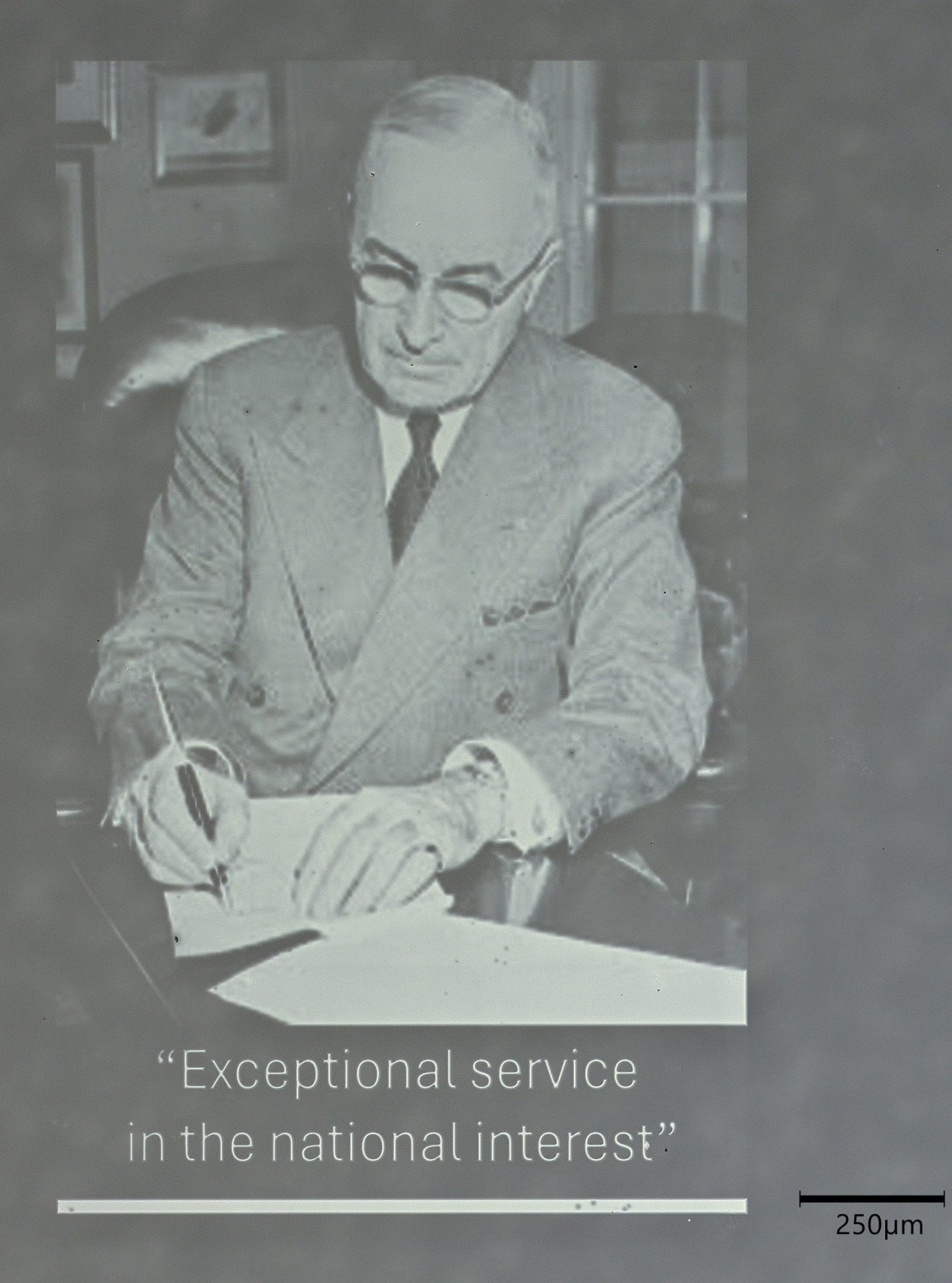

Grayscale Lithography by Annealed Resin Engineering (GLARE)

Novel grayscale lithography technique delivers 100x cost reduction and same-day mask production for enhanced microfabrication capabilities across industries

Business Problem

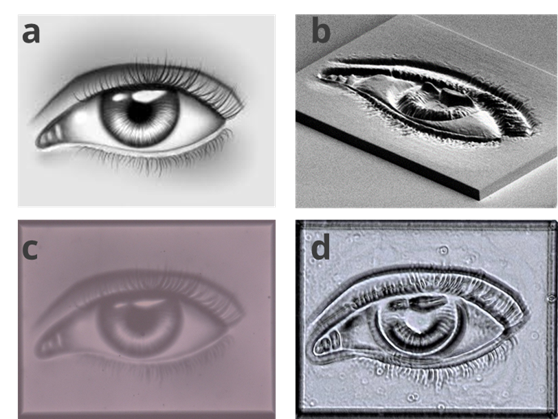

Grayscale Lithography by Annealed Resin Engineering (GLARE) offers industry partners a new way to create special masks used in manufacturing tiny, precise parts for things like virtual reality headsets and advanced electronics. These masks serve as stencils that help shape materials into very detailed

three-dimensional designs. Traditional analog grayscale lithography masks are costly and time-consuming to produce, often requiring up to three weeks to manufacture and costing approximately

$25,000 per mask. This high barrier limits access for many potential users, particularly startups and smaller companies, who may lack the resources to invest in such expensive processes. As a result, many innovators are unable to explore advanced microfabrication techniques that could enhance their products and services.

Customer Need

Industries such as augmented and virtual reality (AR/VR), semiconductor manufacturing, and optical component production require high-precision microfabrication to create intricate designs that meet their performance standards. These customers need a method that not only reduces costs but also accelerates the production timeline for grayscale masks, allowing for faster time-to-market for new

products. The ability to iterate designs in a single day is essential for innovation in these fields, as it enables rapid iterative exploration of fabrication dependencies and nonlinearity which can be difficult to identify during design.

Sandia Approach

Researchers at Sandia National Laboratories have developed GLARE, which enhances the production of grayscale photolithography masks through the pyrolysis of multi-photon-written resist structures on transparent substrates such as quartz, fused silica, or glass. This innovative approach converts 2.5D polymer patterns into carbon masks with varying thicknesses, allowing for different levels of light transmission to be achieved. GLARE enables same-day mask production at a cost of less than $200, representing a 100x cost reduction compared to traditional methods. GLARE has compatibility with commercial off-the-shelf materials and equipment.

Competitive Advantage

GLARE is the first new practical true grayscale contact lithography technique developed in more than 30 years. It offers significant improvements over existing technologies by using non-specialty equipment, which broadens the potential market size and makes the technology more accessible to a wider range of users. The ability to produce masks quickly and affordably allows for rapid design iterations, avoiding the limitations of the traditional “first time right” approach that can stifle creativity and innovation. GLARE makes high-precision microfabrication accessible to a wider range of innovators, including those who may have previously been excluded due to high costs.

Next Steps

Diffractive optical production samples are available for demonstration.

Sandia is seeking partners to develop and commercialize this technology. For more information, please contact Sandia National Laboratories’ Licensing and Technology Transfer office.

- Cost efficiency: GLARE reduces mask production costs to less than $200, enabling broader access to grayscale lithography.

- Speed: The technology facilitates same-day mask production, allowing for rapid

design iterations and innovation that can keep pace with market demands. - Compatibility: GLARE is designed to work with commercial off-the-shelf materials

and equipment, enhancing usability and simplifying the integration process.

- Augmented and virtual reality (AR/VR): Microlens arrays for AR/VR devices, which enhance user experiences by improving image quality and depth perception.

- Semiconductor manufacturing: Gratings for spectroscopy, used in scientific research and analysis to separate light into its component wavelengths.

- Optical component production: Advanced projectors for optical beam shaping, which can improve the performance of displays and imaging systems.

SD 16812

Published2/20/2026