Low Temperature Gasoline Combustion

A high-performance engine technology to replace diesel engines

While electrification is playing a major role in reducing greenhouse gas (GHG) emissions from automobiles and light trucks, practical considerations are likely to make internal combustion (IC) engines the power system of choice for heavy duty (HD) line-haul trucks, some medium-duty (MD) trucks, and most off-road equipment for many decades to come. These vehicles, powered mainly by diesel engines, represent a large potential market for IC engines with better performance.

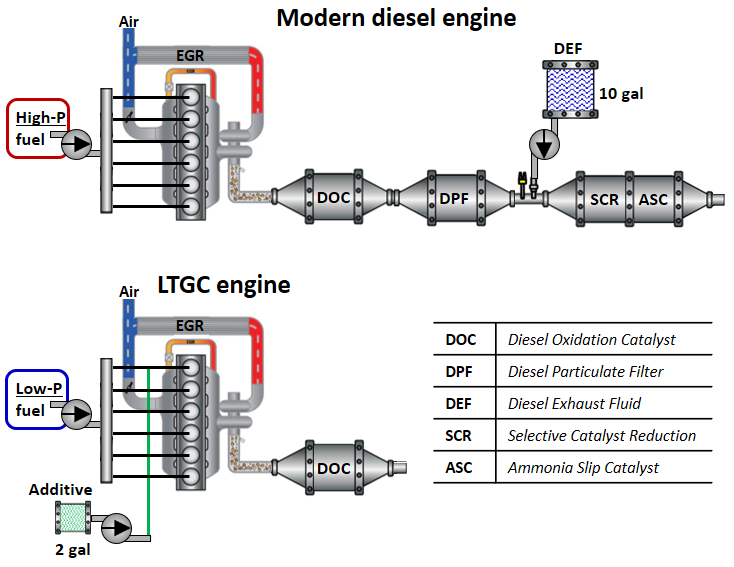

Low-temperature gasoline combustion (LTGC) is a new IC-engine process that has been shown to have much lower fuel consumption and vastly lower emissions of particulates and NOx capable of reducing the cost of exhaust after treatment systems. Nearly half the cost of a modern diesel engine is for exhaust after treatment components required to meet current exhaust-emission standards. In contrast, an LTGC engine has far lower NOx and particulate emissions, eliminating the need for a diesel particulate filter (DPF) and the selective catalytic reduction (SCR) system for NOx control – including the associated ammonia slip catalyst (ASC) and diesel exhaust fluid (DEF) dosing system. A small additive tank is required for LTGC; the additive tank requires refilling only at service intervals whereas DEF must be added to approximately every fourth tank of fuel. Accordingly, the initial cost of an LTGC engine and after treatment system is approximately 30% less than that of a diesel. Additional savings may be accrued due to the lower pressure fuel injection system. Developed though more than two decades of research at Sandia National Laboratories, this work has resulted in patented technologies that overcome the problems associated with low-temperature combustion, making LTGC engines practical for HD and MD trucks and off-road equipment.

- engines will reduce fuel consumption compared with the market-leading diesel by 7-25% for nearly all relevant operating conditions

- Negligible engine-out particulate emissions

- Very low NOx emissions do NOT require expensive after-treatment (as used on diesel engines)

- Lower total cost of ownership compared to diesel technology due to lower fuel and engine/after treatment costs

- Lower GHG emissions than diesel and even lower than electrified technologies in many markets

- Does not require special charge heating devices like competing gasoline compression ignition techniques

- Compatible with commercial gasoline, requiring no new infrastructure

- Medium- and heavy-duty on-road applications

- Off-road applications, including construction, agriculture, and power generation

- Ground transportation in slow-to-electrify markets such as emerging countries

- Automotive

SD 13291

Published3/29/2022

Last Updated3/29/2022