Tandem Conversion of Mixed Algal Biomass

An integrated, high-efficiency conversion process for producing high purity biocrude oils, alcohols, and biofuels from wet algal biomass with minimal waste

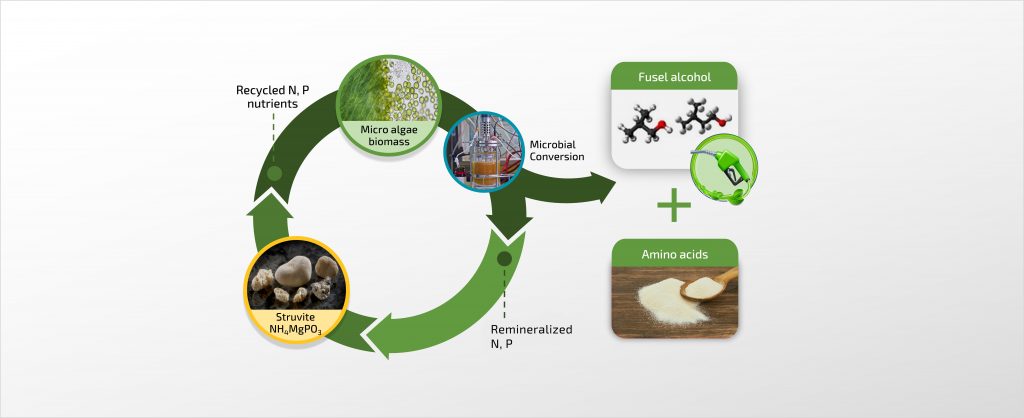

Algae represent a promising biomass crop for supplying renewable biofuels and useful industrial chemicals, however, the processing of algal biomass to produce pure, low nitrogen bio-oils is both highly energy intensive and produces significant waste. New industrial processes that reduce the energy use and/or minimize waste production are needed to make algal-derived fuels economically feasible and closer to realizing their potential as a renewable liquid fuel source.

To address this challenge, researchers at Sandia National Laboratories have developed a consolidated, high-efficiency process for producing biocrude oils, alcohols, and protein co-products from wet algal biomass. By leveraging tandem biochemical and thermochemical processing techniques, researchers greatly reduced energy requirements compared to refining processes where algal biomass is dried prior to refinement. Specifically, a two-phase thermochemical pre-treatment step segregates fermentation-inactivating biomolecules, greatly increasing process efficiency. This process enables the utilization of all algal biochemical intermediates for a variety of chemical products, increasing process production value and reducing waste generation.

- High efficiency conversion of wet algal biomass

- Eliminates the need for drying algal biomass and utilizes all available algal biocomponents

- Reduces fermentation product toxicity

- Compatible with existing petrochemical infrastructure

- Biofuels

- Refining

- Agriculture

SD# 13107

Published2/24/2020

Last Updated2/24/2020