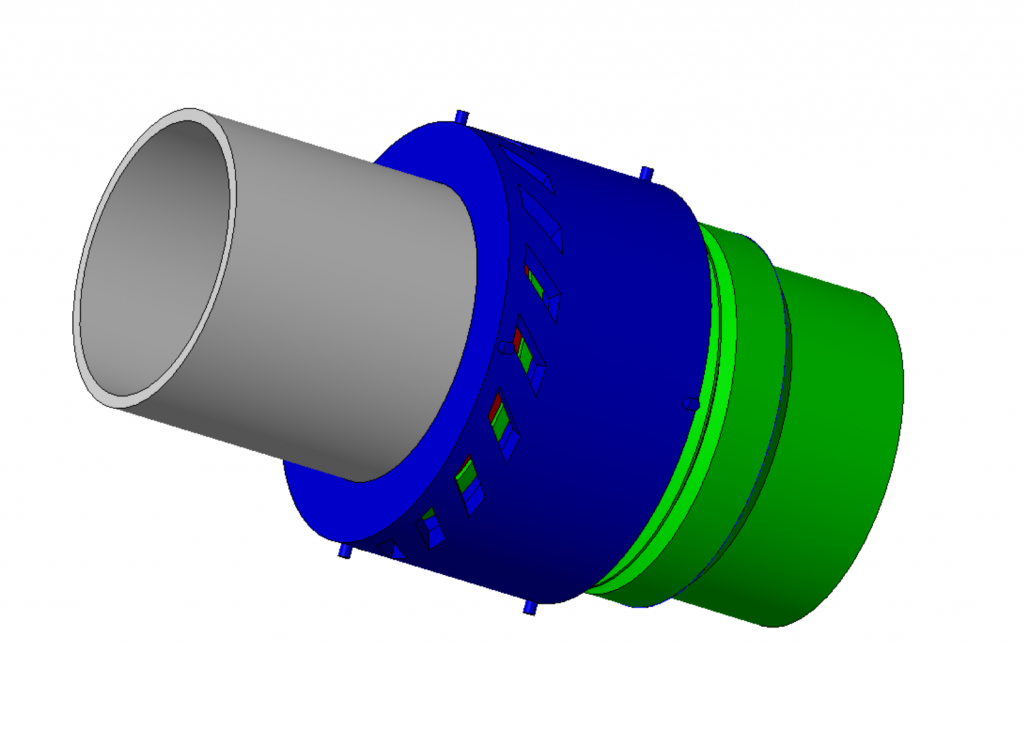

Spring Drive Fitting

Design and manufacturing companies specializing in valves, tubes, and other gas and fluid system components continue to battle the age-old problem of fitting pipes and tubing together quickly and reliably. The Spring Drive Fitting addresses this challenge, bridging the gap between solutions for small diameter tube fittings commonly seen in high pressure, low flow area pneumatic systems, and solutions for large flanges used in low pressure, high flow area hydraulic systems.

The Spring Drive Fitting integrates with existing technologies for joining small diameter tube fittings and combines the benefits of a wave spring and threaded connection, therefore eliminating the problem of friction limiting preload during installation, which plagues connections between 2” and 10” in diameter.The fitting consists of 3 elements: a fitting body and driving ferrule, along with the Spring Drive. To install the fitting, the Spring Drive is first elongated by elastically stretching the integrated preloading beams. The Spring Drive can be stored in the preloaded state via special tooling using the exterior pins. The Spring Drive is then assembled snug to the fitting body and driving ferrule. Removing the exterior tooling from the Spring Drive transfers the preload stored in the elongated preloading beams into the joint and contracts the Spring Drive. This drives the ferrule into the tube and secures the fitting into place.

- Can be integrated into existing joining technologies

- Reliable joint preloading

- Robust design

- Applicable to wide range of pipe diameters

- Design, manufacture, assembly of valves, tubes, and other gas and fluid system components

SD# 14713

Published1/9/2020

Last Updated1/9/2020