Twistact

A fundamentally new type of rotary electrical contact that addresses short operating lifetime due to sliding-contact wear and electrical arcing associated with contact bounce

Researchers at Sandia National Laboratories developed a fundamentally new type of rotary electrical contact that addresses the two limitations of conventional brush/slip ring technology: (1) short operating lifetime due to sliding-contact wear, and (2) electrical arcing associated with contact bounce. Sandia’s Twistact technology has a wide variety of potential applications, but was initially motivated by the need to eliminate rare earth magnets in utility-scale direct-drive wind turbines. As wind turbines are being scaled up in size to achieve better economies of scale, direct-drive wind turbine technology is being adopted by the wind industry to eliminate gearbox lifetime limitations. However, the rare-earth magnets used in these permanent-magnet rotor assemblies of direct-drive wind turbines present two challenges: high initial cost and the supply chain uncertainties of reliance on rare earth metals. Rare earth metals such as neodymium and dysprosium have always been in short supply, and competing applications like electric vehicles are increasing demand. The unpredictability of the future rare earth supply chain is a hindrance to large scale proliferation of wind power because it increases risk to investor return on investment. Moreover, the mining of rare earth metals is notorious for its adverse environmental impact.

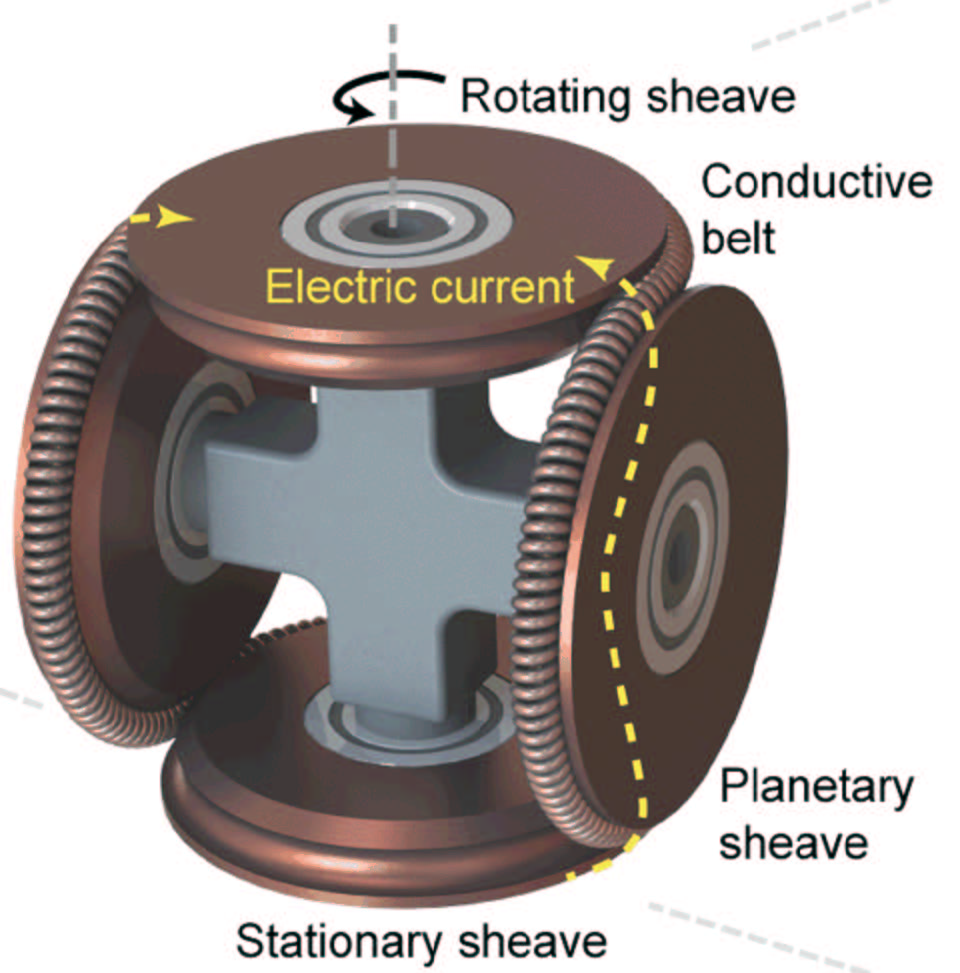

Sandia’s Twistact technology provides a solution both to high maintenance brush/slip ring assemblies and rare earth metal dependent wind turbines. Twistact technology comprises a pure-rolling-contact device that transmits electrical current between a stationary and rotating frame (or two rotating assemblies having different speeds and/or direction of rotation) along an ultra-low resistance path (e.g. 1 milliohm). Twistact devices accomplish pure-rolling-contact galvanic connection using a flexible, electrically conductive belt and a matching set of epicyclic sheaves. Laboratory testing has proven that a single Twistact device will be capable of operating over the full 30-year service time of a multi-megawatt direct-drive wind turbine without maintenance or replacement. A technoeconomic analysis study undertaken by National Renewable Energy Laboratory on behalf of Department of Energy determined that the substitution of rare-earth magnets with a wire-wound rotor and Twistact module in a 10 MW direct-drive wind turbine eliminates the need for rare earth magnets without incurring any penalties in power generation efficiency or levelized cost of energy (LCOE). Having completed all of the milestones of its six-year R&D program on Twistact technology, Sandia is now ready to work with generator OEMs to assist with the transfer of Twistact technology into next generation direct-drive wind turbines. Sandia is also open to partnering on the development of high-rpm Twistact technology for applications such as electric vehicles or doubly-fed induction generators.

- Eliminates reliance on rare earth magnets

- No maintenance or replacement costs

- Wind turbines

- Synchronous motors and generators

- Doubly-fed induction generators

- Electrified railways

- Radar towers

- Grounding of rotating assemblies (e.g. lighting protection)

- Brush/slip ring replacement in existing applications

- Propelling wind energy innovation

Sandia National Laboratories media release (April 2022)

SD#12001

Published2/25/2019

Last Updated2/25/2019